OPTIONS

39

7/53

AFTERCOOLER AND WATER

SEPARATOR

OPERATING INSTRUCTIONS

The compressed air exits the separator tank through the top cover

piping, and will then travel into the aftercooler inlet side.

The aftercooler is cooled by the incoming compressor package air.

The compressed air and condensate (water with a small amount of

compressor lubricant) exits the aftercooler and enters the moisture

separator, where most of the condensate is removed.

At the bottom of the moisture separator a strainer and constant-bleed

orifice is fitted, which are sized to allow the maximum flow of

condensate while minimising compressed air loss.

A second condensate drain valve is mounted on the aftercooler body,

this valve will open on machine shutdown thereby allowing any

remaining condensate in the aftercooler to drain. This is to prevent

cooler damage at freezing temperatures.

These drains are plugged through the compressor frame and will expel

condensation to atmosphere. Should site contamination by this

condensate be prohibited, the user can connect an additional section

of drain hose and route into an allowed drain point.

MAINTENANCE

Daily Maintenance:

Verify, during full-load (maximum compressed air delivery) that

condensate can be seen to drain from the water separator drain hose.

Weekly Maintenance:

•

Verify that the piping from the orifice purge points are not clogged.

•

Clean the inside of the water separator housing.

Water separator maintenance:

•

With engine stopped, ensure pressure is relieved from air system.

•

Remove any hose connected to the water separator housing.

Inspect fittings and hoses for any blockage. Clean if necessary.

•

Remove and clean the water separator float.

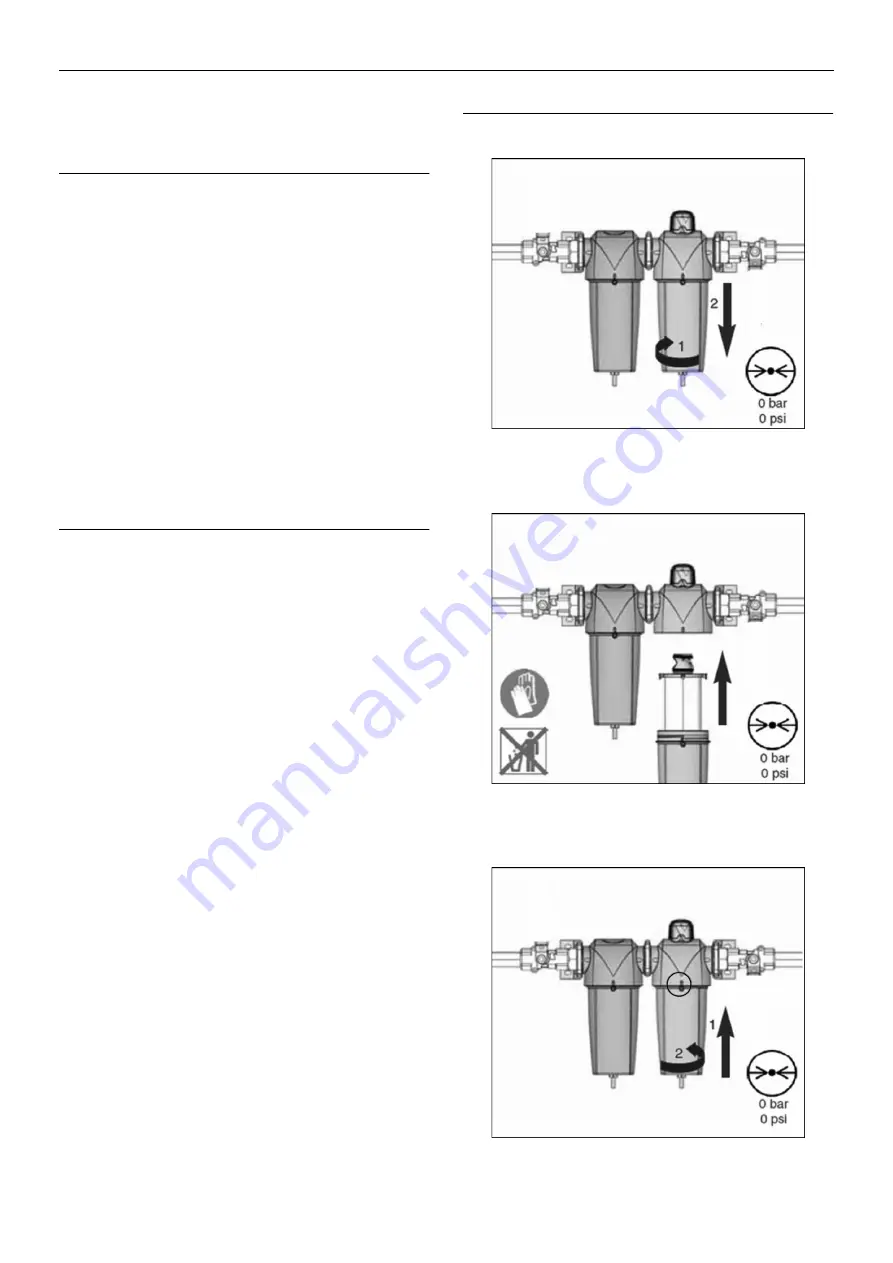

PRIMARY AND SECONDARY FILTER MAINTENANCE

(where used)

FIGURE 1.

FIGURE 2.

FIGURE 3.

Summary of Contents for 7/53

Page 2: ......

Page 4: ......

Page 11: ...DECALS 7 7 53 Engine oil drain...

Page 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

Page 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

Page 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Page 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Page 58: ......

Page 59: ......

Page 60: ......