30

PERIODICAL INSPECTION AND MAINTENANCE

.

9/235

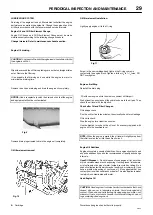

COOLING SYSTEM

Coolant Change

The coolant must be changed at intervals of 1000 hours or twelve

months, whichever come first.

If the coolant becomes sludged up it will lead to engine overheating or

coolant blow

−

off from the radiator.

Coolant draining

.

WARNING:

Hot engine coolant and steam can cause injury. When

adding to or draining coolant or antifreeze solution from the en-

gine radiator, stop the engine at least one minute prior to releasing

the radiator filler cap. Using a cloth to protect the hand, slowly re-

lease the filler cap, absorbing any released fluid with the cloth. Do

not remove the filler cap until all excess fluid is released and the

engine cooling system fully depressurised.

WARNING:

Follow the instructions provided by the antifreeze

supplier when adding or draining the antifreeze solution. It is

advisable to wear personal protective equipment to prevent skin

and eye contact with the antifreeze solution.

Remove the radiator cap.

Slacken the bottom radiator hose clamp to drain the coolant from the

radiator.

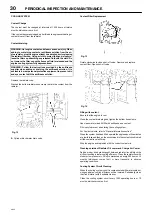

Fig.

12

A

Cylinder block water drain valve

Coolant Filter Replacement

Fig.

13

Rotate clockwise to close shut

−

off valve. Remove and replace

coolant filter. Open shut

−

off valve

Fig.

14

Filling with coolant

Ensure that the engine is cool.

Close the coolant drain plug and tighten the bottom hose clamp.

Use clean water mixed 50/50 with antifreeze as a coolant.

Fill slowly to prevent air entering the cooling system.

For Coolant volume, refer to ”General Information section”

When the system has been filled, operate the engine about five minutes

at a low idle speed, then as the air contained in the coolant circuit is bled

off the coolant level will drop.

Stop the engine and replenish with the correct coolant mix.

Cleaning outside of Radiator, Oil cooler and Charge Air Cooler

Debris, mud or dried grass caught between radiator fins will block the

air flow, resulting in lower cooling efficiency. Clean the radiator fins with

steam or low pressure (< 5 Bar) compressed air every 250 hours or 3

months (whichever comes first) or more frequently in adverse

operating conditions.

Cooling System Circuit Cleaning

When the cooling system circuit is contaminated with water scales or

sludge particles, cooling efficiency will be lowered. Periodically clean

the circuit interior with a suitable cleaner.

Clean the cooling system circuit every 1000 operating hours or 12

months, whichever comes first.