MAINTENANCE

44

9/235

. all hazards present are known (e.g. pressurised components,

electrically live components, removed panels, covers and guards,

extreme temperatures, inflow and outflow of air, intermittently moving

parts, safety valve discharge etc.).

. appropriate personal protective equipment is worn.

. loose clothing, jewellery, long hair etc. is made safe.

. warning signs indicating that

Maintenance Work is in Progress

are

posted in a position that can be clearly seen.

Upon completion of maintenance tasks and prior to returning

the machine into service, ensure that:

−

. the machine is suitably tested.

. all guards and safety protection devices are refitted.

. all panels are replaced, canopy and doors closed.

. hazardous materials are effectively contained and disposed of.

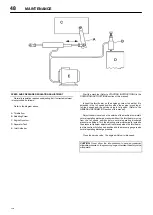

PROTECTIVE SHUTDOWN SYSTEM

Refer to the Wedge diagnostic display codes table for a listing of

shutdown conditions.

Low engine fuel level switch.

Test the low engine fuel level switch circuit as follows:

.

Start the machine.

Note:

Do not press the load button.

.

Disconnect the switch, the machine should shutdown.

.

Re

−

connect the switch.

Test the low engine fuel level switch by removing and operating

the float manually.

CAUTION:

Never remove or replace switches when the machine

is running.

SCAVENGE LINE

The scavenge line runs from the combined orifice/drop tube in the

separator tank, to the orifice fitting located in the airend.

Check that the scavenge line and tube are clear of any

obstruction each time the compressor lubricant is changed as any

blockage will result in oil carryover into the discharge air.

COMPRESSOR OIL FILTER

Refer to the

MAINTENANCE CHART

in this section for the

recommended servicing intervals.

Removal

WARNING: Do not remove the filter(s) without first making sure

that the machine is stopped and the system has been completely

relieved of all air pressure.

(Refer to

STOPPING THE UNIT

in the

OPERATING INSTRUCTIONS

section of this manual).

Clean the exterior of the filter housing and remove the

spin

−

on

element by turning it in a counter

−

clockwise direction.

Inspection

Inspect the oil filter head to be sure the gasket was removed with

the oil filter element. Clean the gasket seal area on the oil filter head.

CAUTION:

If there is any indication of the formation of varnishes,

shellacs or lacquers on the filter element, it is a warning that the

compressor lubricating and cooling oil has deteriorated and that it

should be changed immediately. Refer to LUBRICATION later in this

section.

NOTICE:

Installing a new oil filter element when the old gasket

remains on the filter head, will cause an oil leak and can cause

property damage.

Reassembly

Clean the filter gasket contact area and install the new element by

screwing in a clockwise direction until the gasket makes contact with

the filter housing. Tighten a further

1

/

2

to

3

/

4

of a revolution.

CAUTION:

Start the machine (refer to PRIOR TO STARTING and

STARTING THE UNIT in the OPERATING INSTRUCTIONS section

of this manual) and check for leakage before the machine is put back

into service.

COMPRESSOR OIL SEPARATOR ELEMENT

Refer to the

MAINTENANCE CHART

in this section for the

recommended servicing intervals.

If, however, the element has to be replaced, then proceed as

follows:

Removal

WARNING: Do not remove the filter(s) without first making sure

that the machine is stopped and the system has been completely

relieved of all air pressure.

(Refer to

STOPPING THE UNIT

in the

OPERATING INSTRUCTIONS

section of this manual).

Disconnect all hoses and tubes from the separator tank cover plate.

Remove the drop

−

tube from the separator tank cover plate and then

remove the cover plate. Remove the separator element.

Inspection

Examine the filter element. Examine all hoses and tubes, and

replace if necessary.

Reassembly

Thoroughly clean the orifice/drop tube and filter gasket contact area

before reassembly. Install the new element.

WARNING

Do not remove the staple from the anti

−

static gasket on the

separator element since it serves to ground any possible static

build

−

up.

Do not use gasket sealant since this will affect electrical

conductance.