MAINTENANCE

48

9/235

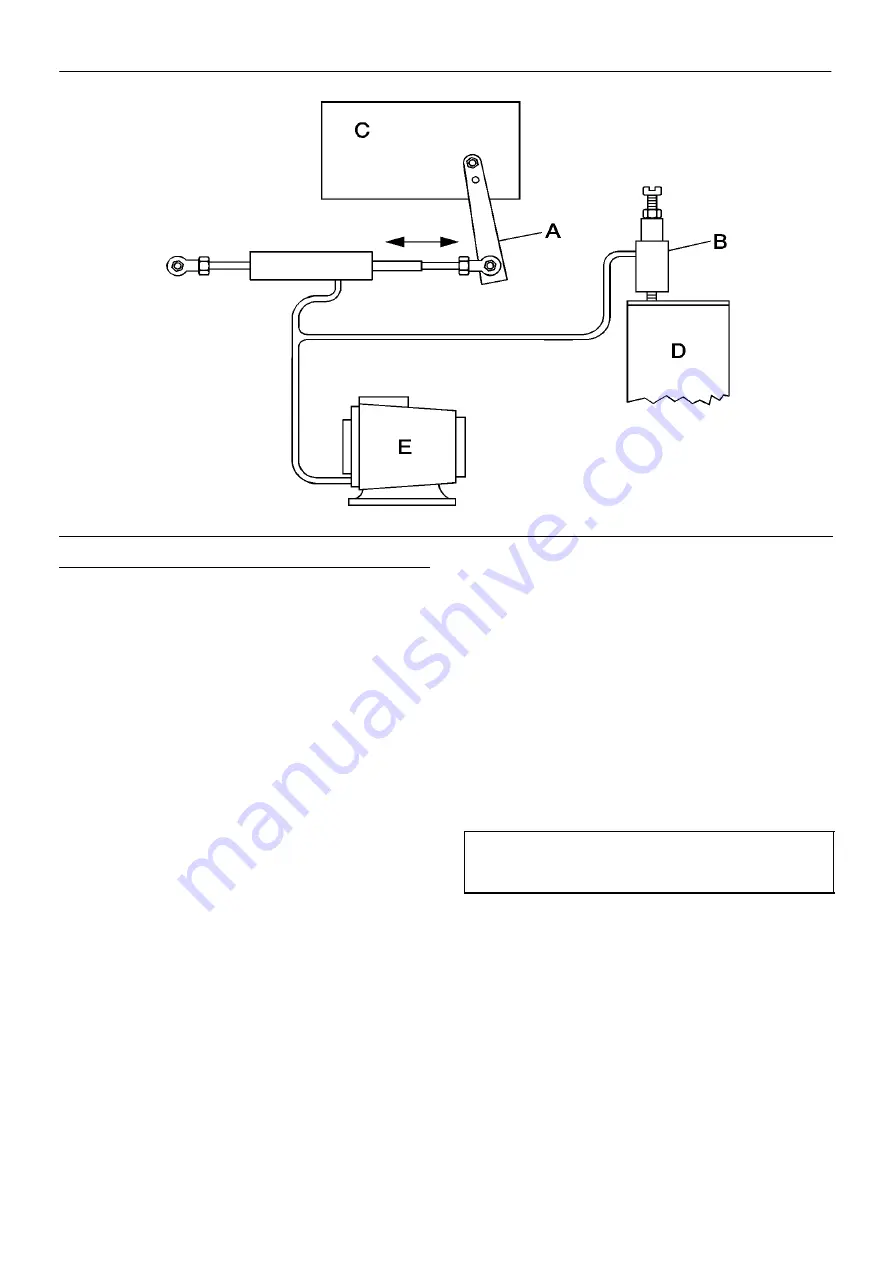

SPEED AND PRESSURE REGULATION ADJUSTMENT

Normally, regulation requires no adjusting, but if correct adjustment

is lost, proceed as follows:

Refer to the diagram above.

A. Throttle Arm

B. Adjusting Screw

C. Engine Governor

D. Separator Tank

E. Inlet Unloader

Start the machine (Refer to

STARTING INSTRUCTIONS

in the

OPERATING INSTRUCTIONS

section of this manual

).

Inspect the throttle arm on the engine governor to see that it is

extended in the full speed position when the engine is running at

full

−

load speed and the service valve is fully open. (Refer to the

GENERAL INFORMATION section of this manual).

Adjust the service valve on the outside of the machine to maintain

normal operating discharge pressure without the throttle arm moving

from the full speed position before normal operating discharge

pressure is attained. Turn the adjusting screw clockwise to increase

the pressure.Optimum adjustment is achieved when the throttle arm

just moves from its full speed position and the pressure gauge reads

normal operating discharge pressure.

Close the service valve. The engine will slow to idle speed.

CAUTION:

Never allow the idle pressure to exceed maximum

allowable pressure on the pressure gauge, otherwise the safety valve

will operate.