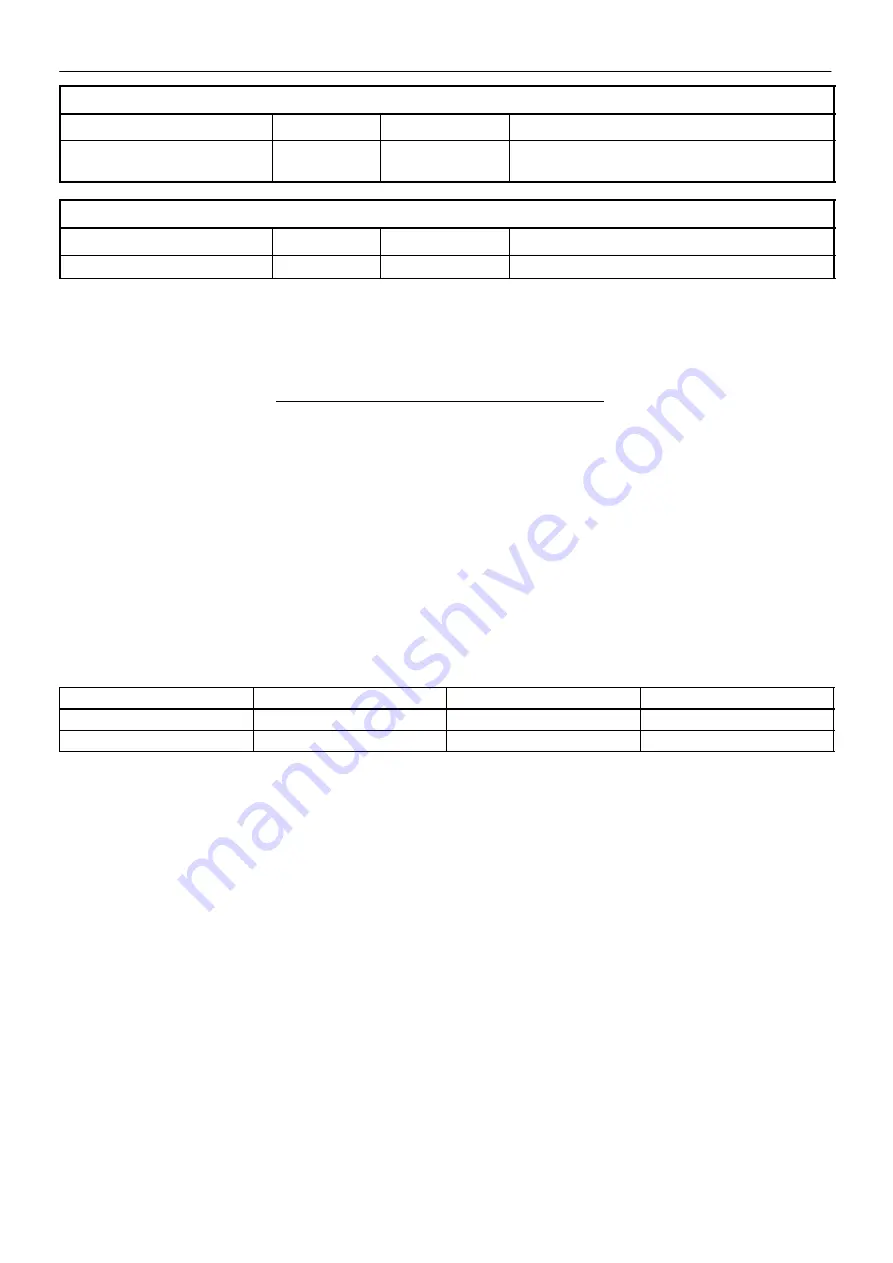

WARRANTY

5

9/235

AIREND EXCHANGE

MONTHS

HOURS

COMMENTS

AIREND

24

4,000

60 MONTHS / 10,000 HRS. AVAILABLE UNDER

CONDITIONS.

CONSTRUCTION TOOLS

MONTHS

HOURS

COMMENTS

CONSTRUCTION TOOLS

12

N/A

NOTE: Actual warranty times may change.

Consult the Manufacturer’s warranty policy as shipped with each

new product.

Extended Limited Airend Warranty

All machines have the standard airend warranty,

−

The earlier of 24 months from shipment to, or the accumulation of 4000 hours of service by the

initial user.

The warranty against defects will include replacement of the complete Airend, provided the original Airend is returned assembled and unopened.

The optional limited warranty is the earlier of 60 months from shipment to, or the accumulation of 10,000 hours of service. The optional warranty

is limited to defects in major components (rotors, housings, gears and bearings), and is automatically available when the following conditions are met:

1. The original airend is returned assembled and unopened.

2. Submissions of proof that Doosan fluid, filters and separators have been used. Refer to the Operation and Parts manual for the correct fluids, filters

and separator elements required.

3. Submissions of proof that maintenance intervals have been followed.

WARRANTY

TIME

*BARE AIREND

**AIREND COMPONENTS

STANDARD

2YRS / 4,000HRS

100% PARTS & LABOUR

100% PARTS & LABOUR

OPTIONAL

5YRS / 10,000HRS

100% PARTS & LABOUR

0%

*BARE AIREND

−

pertains to major airend parts (rotors, housings, gears and bearings).

**AIREND COMPONENTS

−

pertains to auxiliary attachments to the bare airend (seals, pumps, valves, tubes, hoses, fittings and filter housing).