34

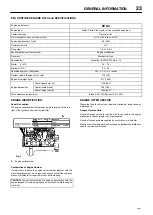

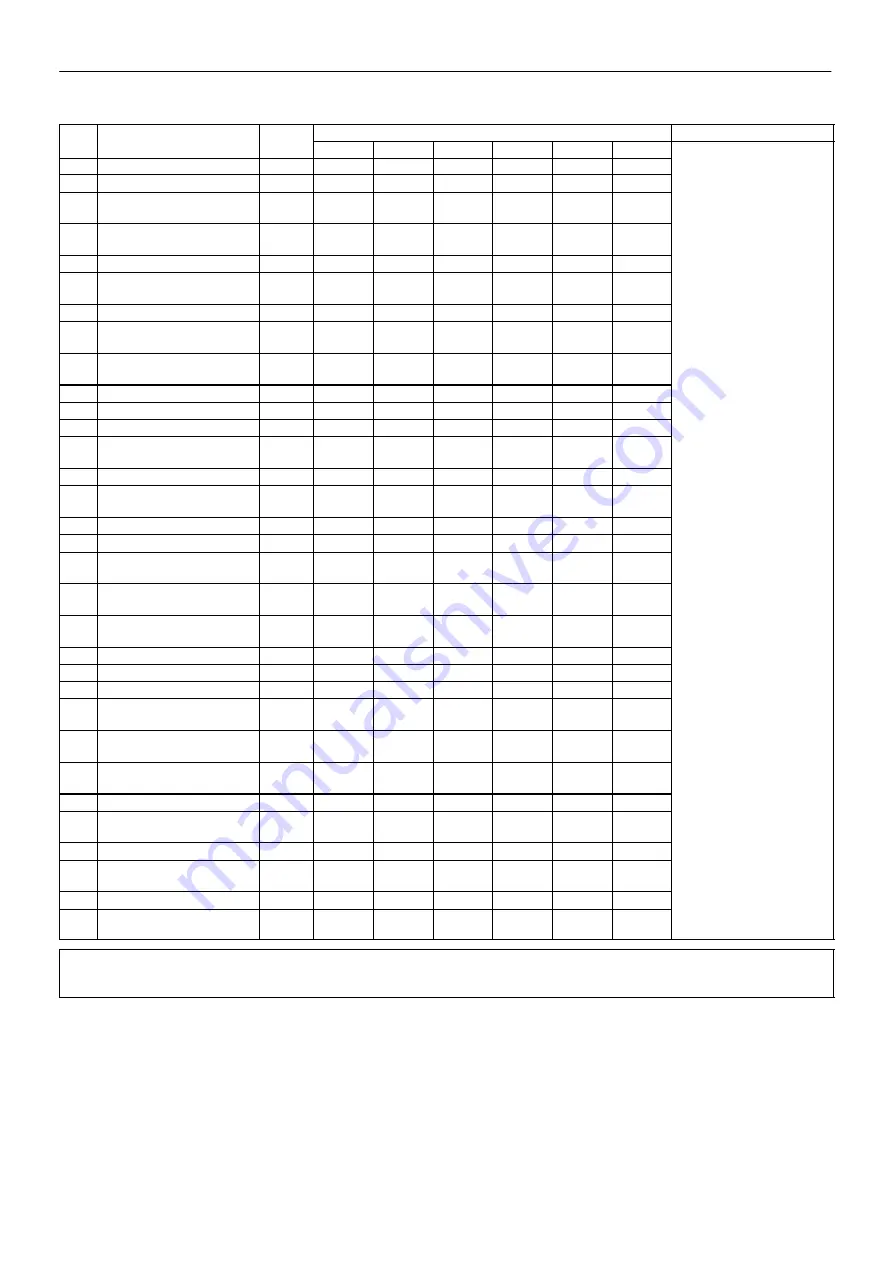

ENGINE MAINTENANCE SCHEDULE

9/235

When performing the following items, the daily inspection items should also be carried out.

No

Description of check

Daily

(operation hours)

Remark

No

Description of check

and maintenance

Daily

250

500

750

1000

1250

1500

1

Oil level

O

2

Oil leakage

O

3

Oil pressure gage reading

(where fitted)

O

4

Oil pressure warning lamp

(where fitted)

O

5

Engine oil replacement

O

O

O

6

Oil filter element

replacement

O

O

O

7

Fuel leakage

O

8

Draining water in fuel

filter/separator

O

See “EXPLANATION

OF

9

Fuel filter element

replacement

O

O

O

See EXPLANATION OF

MAINTENANCE SCHEDULE”

10

Injection nozzle check

(*)

O

11

Coolant level

O

12

Coolant leakage check

O

13

Radiator filler cap fitting

condition

O

14

Fan and belt check

O

O

15

Coolant temperature gage

reading (where fitted)

O

16

Coolant replacement

O

17

Coolant filter replacement

O

18

Radiator external face

cleaning

O

O

O

O

O

O

19

Cooling system circuit

cleaning

O

20

Radiator filler cap

function check

(*)

O

O

O

21

Electrolyte level check

O

22

Battery cleaning

O

23

Battery charge lamp

O

24

Starter and alternator check

and cleaning

(*)

O

25

Wiring and connection

check

O

O

O

26

Air cleaner element

replace

O

O

O

27

Air intake piping

O

28

Engine starting conditions

and noise conditions

O

29

Exhaust smoke condition

O

30

Cylinder compression

pressure

(*)

O

31

Valve clearance check

(*)

O

32

Positive crankcase

ventilation valve cleaning

O

O

Note:

1. After every 1500 hours of operation, the service intervals should be repeated in accordance with this check and maintenance schedule.

2. When servicing on the asterisked

(*)

items is necessary, consult your local Doosan branch or distributor.