•

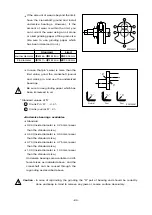

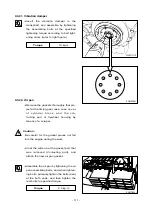

Install a guide bar into a bolt hole on the

crank shaft, and lift the flywheel to align

the dowel pin with the pin hole on the f l y -

w h e e l f o r t e m p o r a r y a s s e m b l y

operation.

•

Coat the adhesive (#271 Loctite) over

the assembling bolts and install bolts in

the remaining holes. After that take out

the guide bar, then install a bolt in the

hole where the guide bar had been

inserted.

•

According to the order of tightening

tighten the fixing bolts using a torque

wrench in a diagonal sequence to speci-

fied torque.

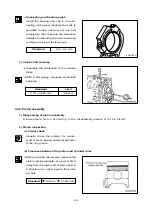

9.3.9. Tacho sensor (Pick-up sensor)

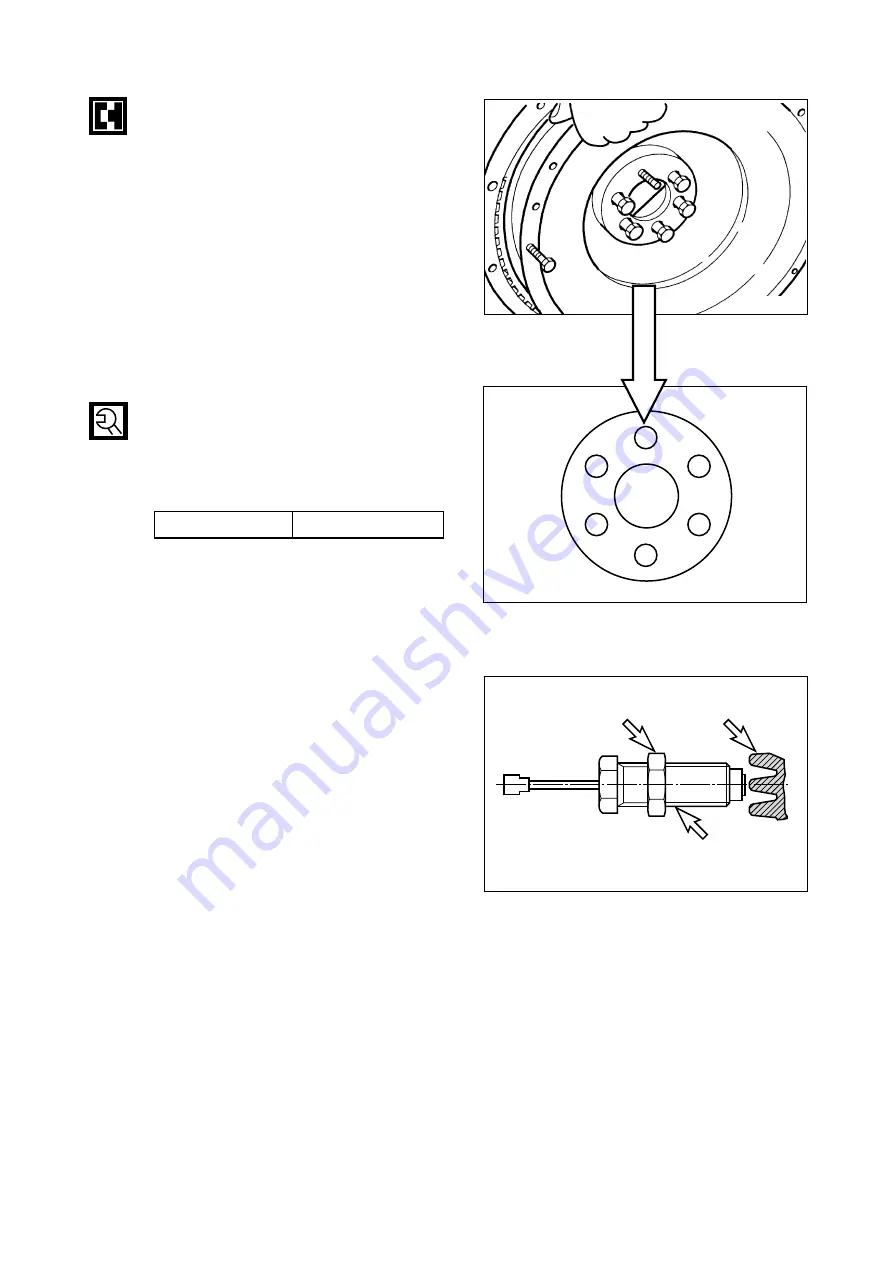

•

Move the lock nut to hexagonal side of

sensor completely.

•

Rotate (CW) the tacho sensor on fly

wheel housing, until the end of it reach

on fly wheel ring gear.

•

Rotate (CCW) the tacho sensor for 270

˚

(gap 1.0 mm) and fix lock nut.

•

Tolerance limit is 27

˚

. (gap ± 0.1 mm)

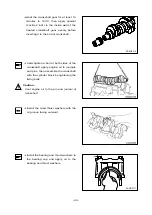

9.3.10. Water chamber cover

•

Coat the adhesive over the water cham-

ber cover (Particular around bolt holes)

and after attaching the gasket, assemble

it to the cylinder block using the bolts for

assembling.

•

As for tightening of bolts, after primarily

tightening the bolts located at the both

ends of cover (4ea at both sides) and

middle bolts (Upper, lower 2ea) , tighten

the rest.

- 102 -

1

5

4

3

6

2

EDM2073I

Torque

18.5 kg

.

m

EPM2030I

Lock nut

Ring gear

M16 x 1.5

EDM2072I

Summary of Contents for D1146

Page 1: ......

Page 57: ...7 2 Trouble Shooting 53 ...

Page 58: ... 54 ...

Page 59: ... 55 ...

Page 60: ... 56 ...

Page 61: ... 57 ...

Page 62: ... 58 ...

Page 63: ... 59 ...