9.2. Inspection

9.2.1. Cylinder block

•

Clean the cylinder block thoroughly, and check for any crack or damage.

•

If there is any crack or severe damage, replace it and if there is minor one, correct it.

•

Check for any clogging or corrosion in the oil passage and water passage.

•

Carry out a leakage test for any crack or air leaking.

Hydraulic test :

Plug each cylinder block's water and oil discharge ports, and apply the air pressure of about

4kg/cm

2

to intake port and soak it in water for about 1 minute to check if there is any leak-

age. (Water temperature : 70

˚

C)

9.2.2. Cylinder head

1) Cylinder head assembly disassembly

(1) Disassemble the cylinder assembly,

and put it on the shelf for assembly or

clean lathe.

Caution :

Prevent any damage to gasket’s contact

surface of the cylinder head.

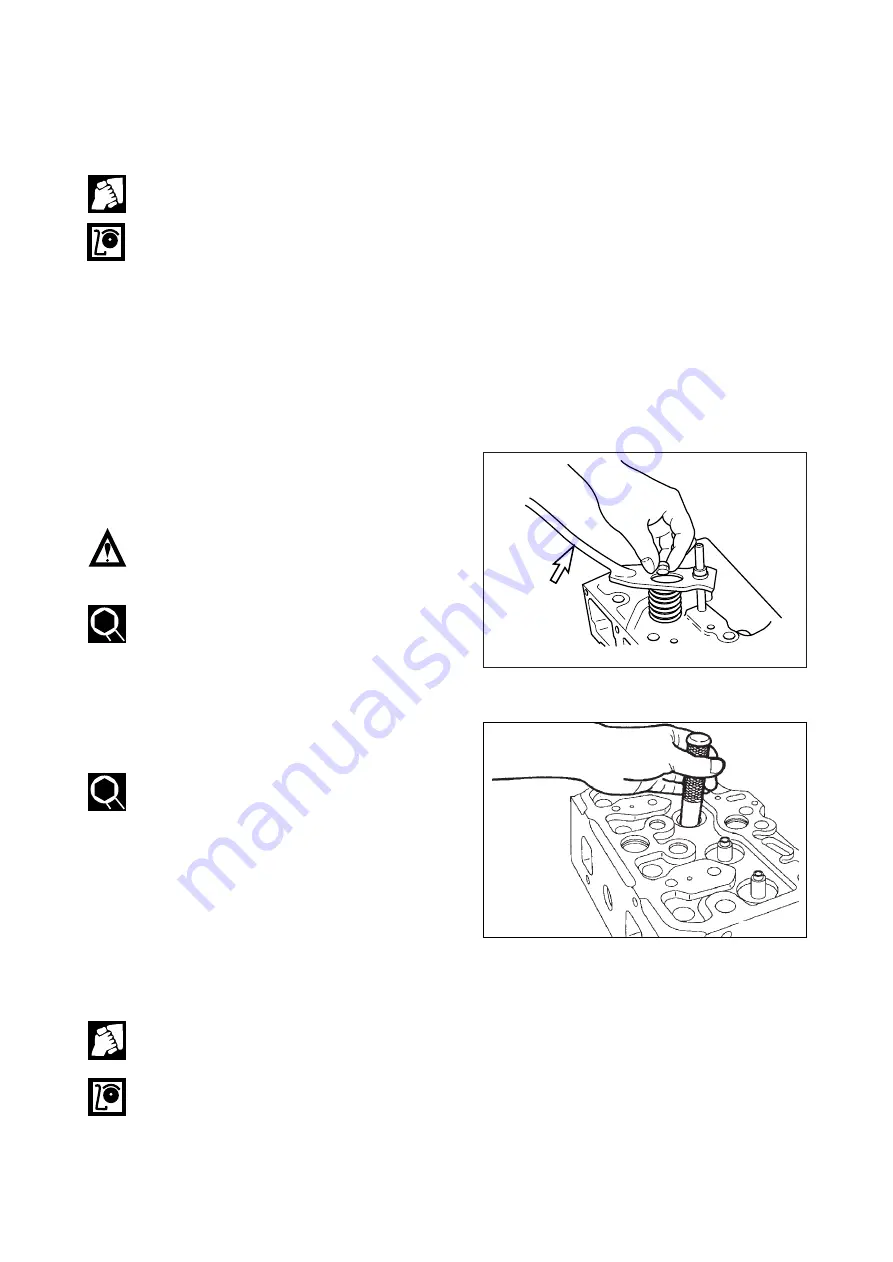

(2) Disassemble the cotter pin, spring,

spring seat pushing valve spring by a

special tool.

(3) Pull out the intake and exhaust valves.

(4) The disassembled parts are kept laid

in turn.

(5) Disassemble the valve stem seal.

(6) By means of the special tool, punch,

pull out a valve guide.

2) Inspection of cylinder head

(1) Check for the cylinder head.

•

Remove carbon from the cylinder head lower surface, and then should be careful not to

scratch the surface.

•

Check any crack or damage that can not found by naked eyes through the hydraulic or

magnetic particle test.

- 79 -

Compressor

the spring

EA0M4007

Compress

the spring

EB5M3019

Summary of Contents for D1146

Page 1: ......

Page 57: ...7 2 Trouble Shooting 53 ...

Page 58: ... 54 ...

Page 59: ... 55 ...

Page 60: ... 56 ...

Page 61: ... 57 ...

Page 62: ... 58 ...

Page 63: ... 59 ...