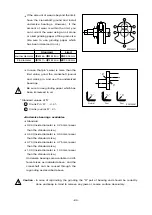

(2) Distortion of lower surface

•

As shown in figure, measure the cylinder

head’s distortion at 6 directions with hor-

izontal ruler and clearance gauge.

•

If the measured value is beyond the limit

value, correct it by means of the fine

grinding paper or grinding machine.

•

If it is beyond the max. allowable value,

replace the cylinder head

<Lower face warp and height>

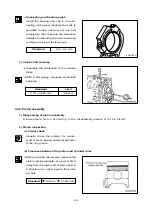

(3) Flatness

Check the flatness of the installing surface of cylinder head’s intake and exhaust m a n i f o l d s

w i t h h o r i z o n t a l r u l e r a n d clearance gauge.

(4) The hydraulic test

The hydraulic test of cylinder head is same as the cylinder block test.

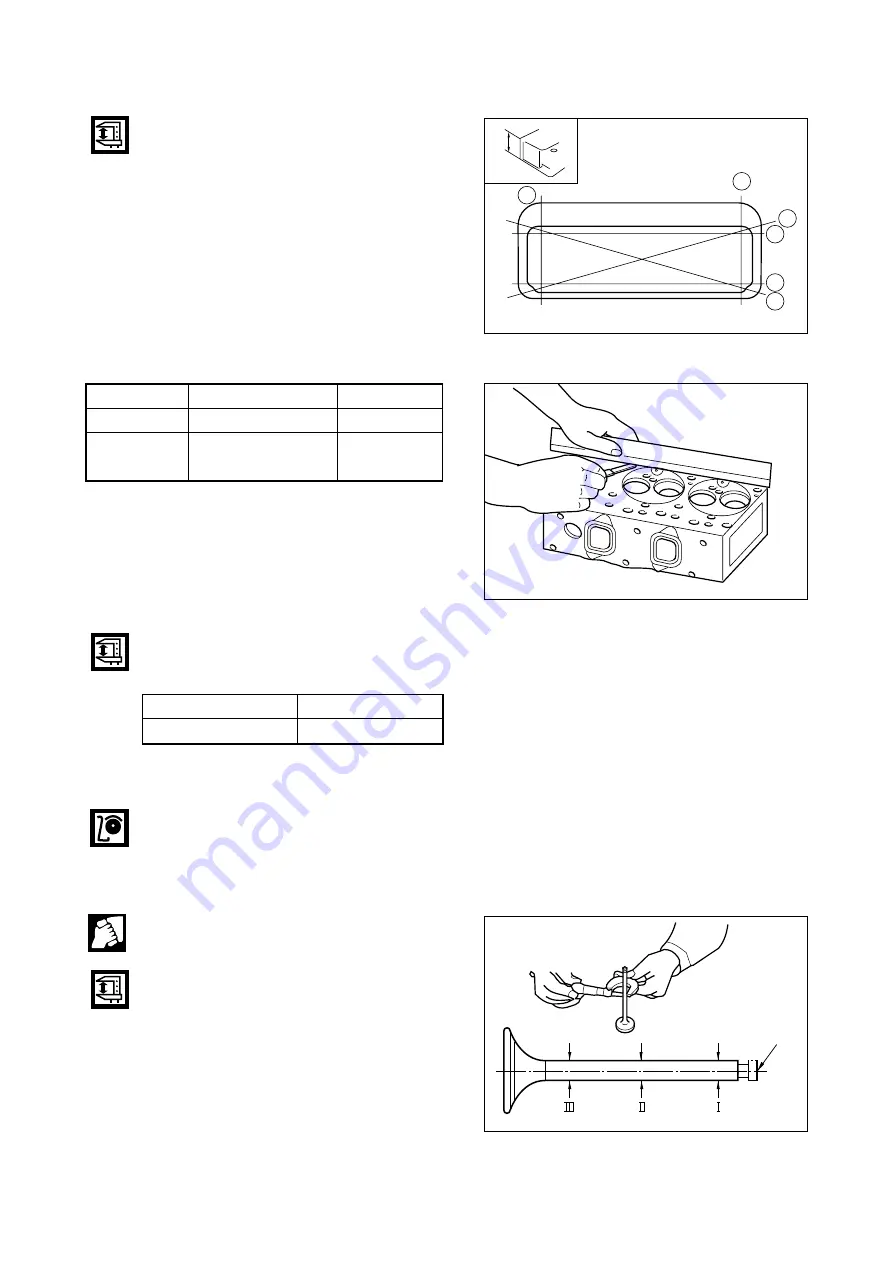

3) Inspection of valve and valve guide

(1) Valve

After cleaning valve with fuel, check it.

•

Valve stem outer diameter

Measure the valve stem outer diameter

at 3 positions (top, middle, and bottom),

and check for any wear and if beyond

the limit value, replace the valve.

- 80 -

(t)

A

B

C

D

E

EA3M2031

F

Standard

Limit

Warp

0.2 mm or less

0.3 mm

Thickness : t

109.9 ~ 110.1 mm

108.4 mm

(reference)

EA9M3020

Standard

Limit

0.05 mm

0.2 mm

EFM2036I

End of stem

Summary of Contents for D1146

Page 1: ......

Page 57: ...7 2 Trouble Shooting 53 ...

Page 58: ... 54 ...

Page 59: ... 55 ...

Page 60: ... 56 ...

Page 61: ... 57 ...

Page 62: ... 58 ...

Page 63: ... 59 ...