•

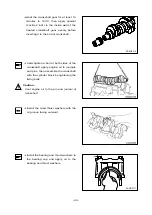

Using a cylinder bore gauge, measure

cylinder liner inside diameter at 3 points

(cylinder top ring contacting face, middle,

and oil ring contacting face on BDC) in a

direction at an angle of 45

˚

.

Take the

mean value with the largest and smallest

values excepted.

•

The clearance is computed by subtracting

the piston outside diameter from the

cylinder liner inside diameter. Replace

either piston or cylinder liner, w h i c h e v e r

d a m a g e d m o r e , i f t h e clearance is

beyond the specified limit.

<Clearance between piston and liner>

3) Piston rings

(1) Visual check

Replace the piston rings with new ones if

detected worn or broken when the engine

is overhauled.

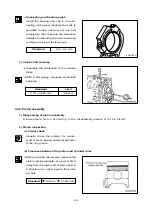

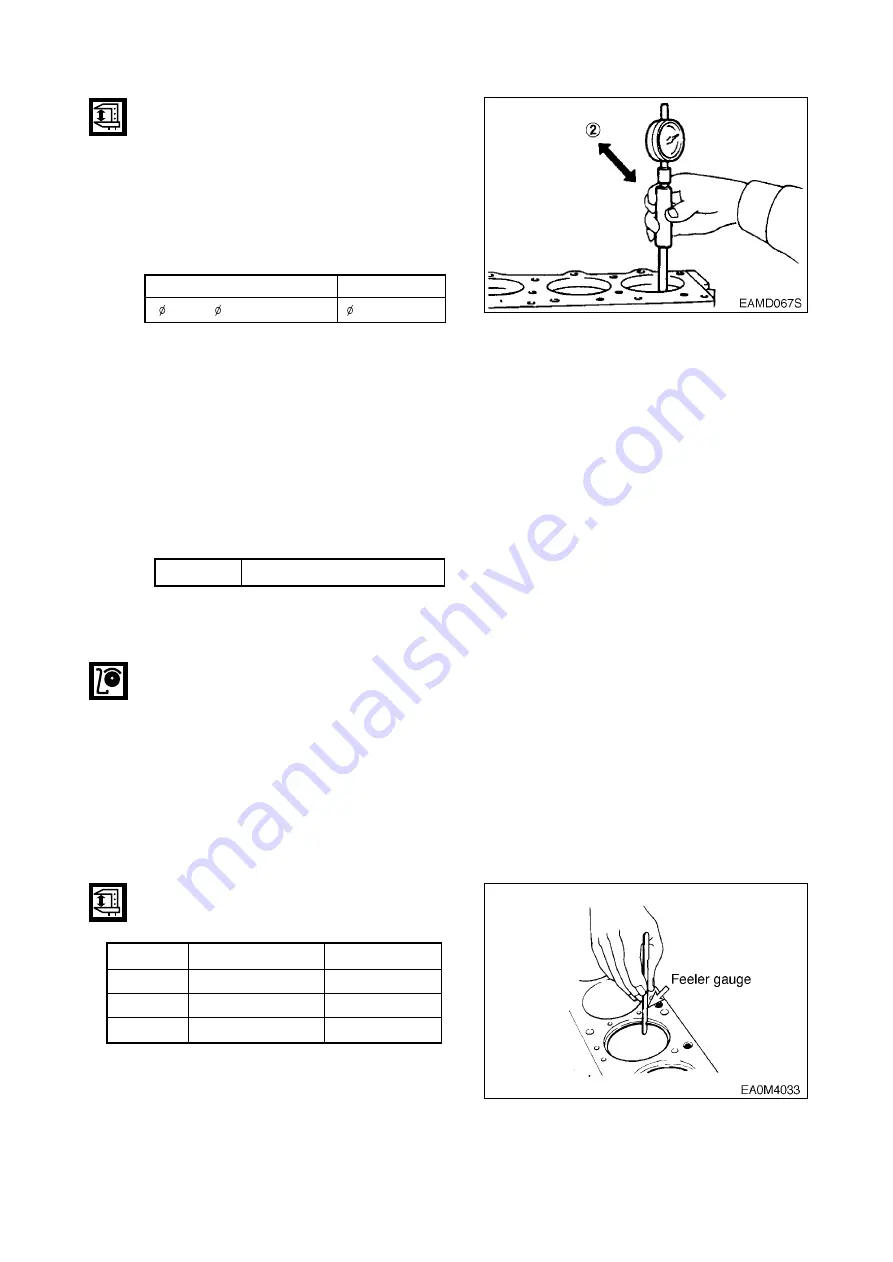

(2) Piston ring gap

•

Insert the piston ring into the upper por-

tion of the cylinder liner bore so that it is

held at a right angle to the cylinder liner

wall.

•

Measure the piston ring gap with a feeler

gauge.

Replace piston rings with new ones if the

gap is beyond the limit.

- 94 -

Standard

Limit

111 ~ 111.022 mm

111.122 mm

Standard

0.103 ~ 0.139 mm

Standard

Limit

Top ring

0.40 ~ 0.60 mm

1.5 mm

2nd ring

0.40 ~ 0.60 mm

1.5 mm

Oil ring

0.30 ~ 0.50 mm

1.5 mm

Summary of Contents for D1146

Page 1: ......

Page 57: ...7 2 Trouble Shooting 53 ...

Page 58: ... 54 ...

Page 59: ... 55 ...

Page 60: ... 56 ...

Page 61: ... 57 ...

Page 62: ... 58 ...

Page 63: ... 59 ...