G424F(FE) Service Manual

Chapter 3. Engine Mechanical System

60

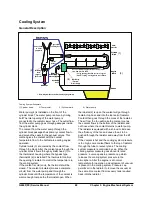

Cooling System

General Description

Cooling System Schematic

1) Cylinder head.

2) Thermostat.

3) Cylinder walls.

4) Water pump.

Water pump (4) is installed on the front of the

cylinder block. The water pump is driven by timing

bolt.The inlet opening of the water pump is

connected to the radiator lower hose. The outlet flow

from the water pump goes through passages inside

the cylinder block.

The coolant from the water pump through the

cylinder block passages has primary coolant flow to

and around the seats for the exhaust valves. This

method gives the coolant with the coolest

temperature flow to the hottest area during engine

operation.

Cylinder walls (3) are cooled by the coolant flow

through the block. After the coolant goes through the

cylinder block it flows through cylinder head (1) to

the thermostat housing, where the bypass type

thermostat (2) is installed. The thermostat controls

the opening to radiator to control the temperature in

the cooling system.

If the coolant is cold (cool), the thermostat will be

closed. The coolant circulates (makes a complete

circuit) from the water pump and through the

cylinder block until the temperature of the coolant is

warm enough to make the thermostat open. When

thermostat (2) is open the coolant will go through

radiator top hose and into the top tank of radiator.

Coolant then goes through the cores of the radiator.

The air from the fan will make the coolant cool as

the coolant flows to the bottom of the radiator and

out hose where the coolant returns to water pump.

The radiator is equipped with a shroud to increase

the efficiency of the fan and cause the air to be

pushed through the radiator and away from the lift

truck.

If the coolant is hot and the cooling system pressure

is too high, some coolant flows to the top of radiator

through the tube to recovery tank. The cooling

system pressure is controlled by cap. When the

cooling system pressure goes above its rated

pressure, a valve opens in pressure cap which

releases the cooling system pressure to the

atmosphere. After the engine is at normal

temperature for operation, a development of vacuum

is present in the cooling system. Pressure cap

permits air in the radiator to remove the vacuum at

the same time coolant from recovery tank is pulled

back into the radiator.

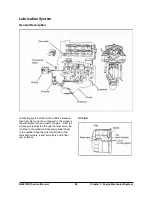

Cam

Carrier

Cylinder

Head

Engine

Block

Oil Pump

Assy

Belt Driven

“Cassette”

Water Pump

Water inlet

(Actual pump inlet

thru rear of pump)

Water Outlet Assy

(attaches to cyl head)

Coolant

Sensor

Note: Cylinder head gasket orifices control water

flow from block to head.

- Large opening (max flow) at rear of engine

- Small “venting” passages between cylinders

Water out

Oil Pan

* Note: Diagram does not reflect actual engine geometry

Blocking

t/stat

(bypass

open cold)

Upper outlet to

ancillary device

Lower outlet

to water

pump inlet

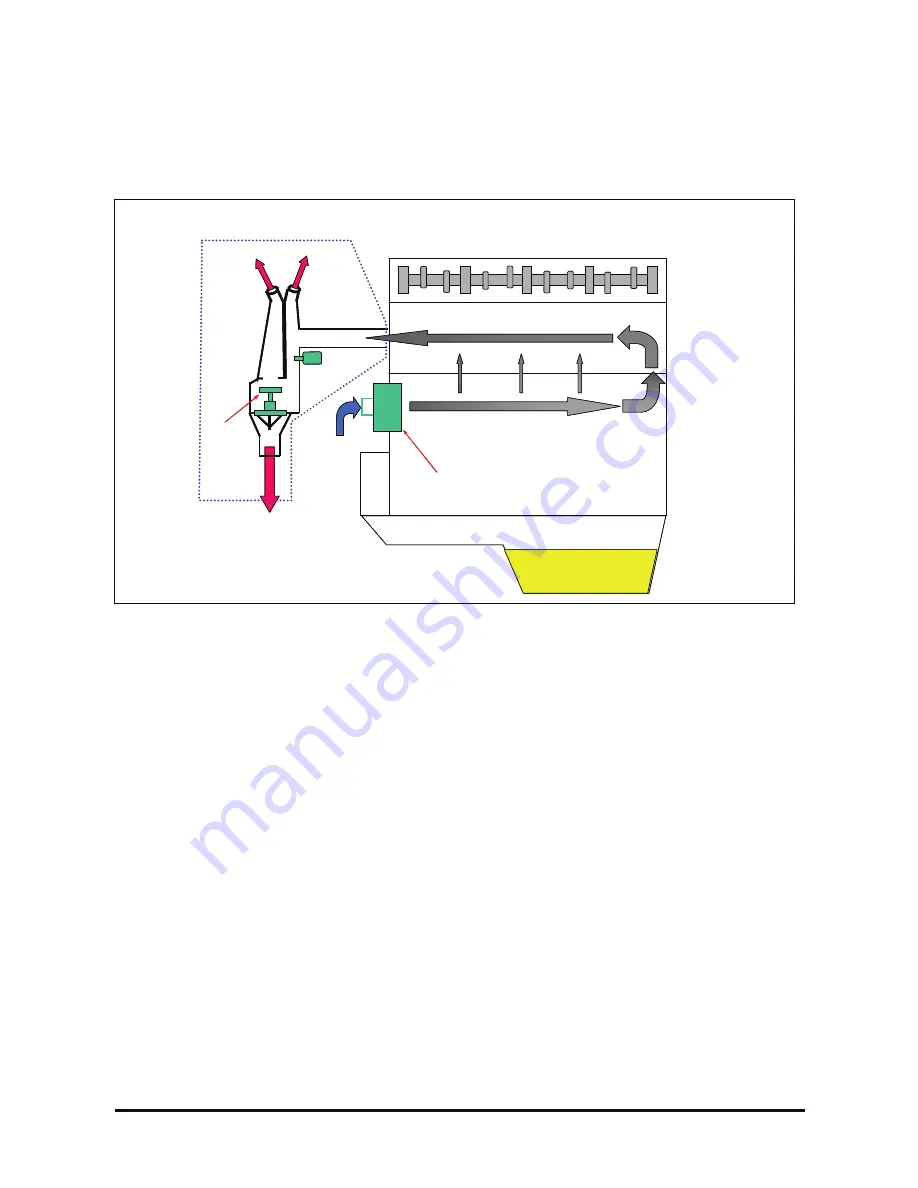

Cam

Carrier

Cylinder

Head

Engine

Block

Oil Pump

Assy

Belt Driven

“Cassette”

Water Pump

Water inlet

(Actual pump inlet

thru rear of pump)

Water Outlet Assy

(attaches to cyl head)

Coolant

Sensor

Note: Cylinder head gasket orifices control water

flow from block to head.

- Large opening (max flow) at rear of engine

- Small “venting” passages between cylinders

Water out

Oil Pan

* Note: Diagram does not reflect actual engine geometry

Blocking

t/stat

(bypass

open cold)

Upper outlet to

ancillary device

Lower outlet

to water

pump inlet

(1)

(3)

(4)

(2)

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...