G424F(FE) Service Manual

Chapter 4. Engine Electrical System

102

Ignition System

Spark-ignited engines require accurate control of

spark timing and spark energy for efficient

combustion. The MI-07 ignition system provides this

control. The system consists of the following

components:

•

SECM

•

Ignition coil drivers *

•

Ignition coil(s) *

•

Crankshaft position sensor *

•

Crankshaft timing wheel *

•

Cam position sensor *

(for sequential ignition or fuel injection onl

y)

•

Cam timing wheel *

(for sequential ignition or fuel injection only)

•

Spark plugs *

The SECM, through use of embedded control

algorithms and calibration variables, determines the

proper time to start energizing the coil and fire the

spark plug. This requires accurate crank/camshaft

position information, an engine speed calculation,

coil energy information, and target spark timing. The

SECM provides a TTL compatible signal for spark

control. The coil must contain the driver circuitry

necessary to energize the primary spark coil

otherwise an intermediary coil driver device must be

provided. The SECM controls spark energy (dwell

time) and spark discharge timing.

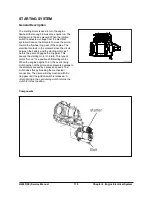

Wasted Spark DIS Ignition System

The G424F and G424FE engine has a wasted spark

ignition system (2 cylinders per coil).

Wasted spark ignition is a type of distributor-less

ignition system where a pair of multi tower coils is

mounted near the spark plugs. The DIS system

eliminates the wear associated with most distributor

type ignition systems. The wasted spark ignition

fires pairs of cylinders at each ignition event. One

cylinder fires on the compression stroke as is normal.

However, the complementary pair in the firing order

is fired simultaneously while that particular cylinder

is on the exhaust stroke. Since the ionized exhaust

gases require little spark energy, the majority of the

ignition energy from the coil goes to the spark plug

in the cylinder on the compression stroke.

The DIS coil pack can be mounted close to the

spark plugs, thereby improving ignition lead routing

and length. There are fewer parts to malfunction on

the DIS system when compared to a distributor type

system.

DIS COMPONENTS

In a typical DIS ignition system, a crankshaft

position sensor generates a basic timing signal by

reading notches on the crankshaft, flywheel, or

harmonic balancer. The crank sensor signal goes to

the small engine control module (SECM), where it is

used to determine firing order and turn the individual

ignition coils on and off.

The operation of the ignition system is essentially

the same as any other ignition system. Each coil has

a low primary resistance (0.4 to 0.6 ohms) and steps

up the primary system voltage from 12 volts to as

much as 40,000 volts to produce a spark for the

spark plug.

It is a direct connection that delivers the hottest

spark possible. Resistor plugs are generally used to

suppress electromagnetic interference (EMI).

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...