G424F(FE) Service Manual

Chapter 5. Engine Management System (EMS)

135

pressure regulator outlet pressure changes by the

same amount and in the same direction. The end

result is that a change in FTV modulation changes

the outlet pressure of the regulator/fuel inlet

pressure of the mixer, and thus the AFR. A major

benefit of this trim system results from the use of

mixer inlet pressure and AVV as the reference

pressure extremes. The pressure differential across

the mixer fuel valve is related to these same two

pressures, and thus so is fuel flow. Given this

arrangement, the bias pressure delta scales with the

fuel cone delta pressure. The result is that the trim

system control authority and resolution on AFR

stays relatively constant for the entire speed and

load range of the engine.

SECM

The Small Engine Control Module (SECM) controls

the LPG lock-off solenoid valve and the FTVs. The

lock-off solenoid is energized when fueling with LPG

and the engine is turning. FTV modulation frequency

will be varied as a function of rpm by the SECM in

order to avoid resonance phenomena in the fuel

system. FTV commands will be altered by the

SECM in order to maintain a stoichiometric air-fuel

ratio. Commands are based primarily on feedback

from the exhaust gas oxygen sensor, with an offset

for fuel temperature.

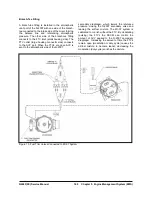

MI-07 LP Fuel Filter

After exiting the fuel tank, liquid propane passes

through a serviceable inline fuel filter to the electric

fuel lock off. Figure 3 shows a typical inline type LP

fuel filter manufactured by Century. The primary

function of the fuel filter is to remove particles and

sediments that have found their way into the tank.

The LP fuel filter will not remove heavy end solids

and paraffins that build up in LPG fuel systems as a

result of vaporization.

Figure 3. Inline LP Fuel Filter

MI-07 Fuel Lock-Off (Electric)

The fuel lock-off is a safety shutoff valve, normally

held closed by spring pressure, which is operated by

an electric solenoid and prevents fuel flow to the

regulator/ converter when the engine is not in

operation. This is the first of three safety locks in the

MI-07 system.

Figure 4. Electric Fuel Lock Assembly

In the MI-07 design, power is supplied to the fuel

lock-off via the main power relay with the SECM

controlling the lock-off ground (earth) connection.

The lock-off remains in a normally closed (NC)

position until the key switch is activated.

This supplies power to the lock-off and the SECM,

but will not open the lock-off via the main power

relay until the SECM provides the lock-off ground

connection. This design gives the SECM full control

of the lock-off while providing additional safety by

closing the fuel lock-off in the unlikely event of a

power failure, wiring failure or module failure.

When the liquid service valve in the fuel container is

opened, liquid propane flows through the LP filter

and through the service line to the fuel lock-off.

Liquid propane enters the lock-off through the 1/4”

NPT liquid inlet port and stops with the lock-off in the

normally closed position. When the engine is

cranked over the main power relay applies power to

the lock-off and the SECM provides the lock-off

ground causing current to flow through the windings

of the solenoid creating a magnetic field. The

strength of this magnetic field is sufficient to lift the

lock-off valve off of its seat against spring pressure.

When the valve is open liquid propane, at tank

pressure, flows through the lock-off outlet to the

pressure regulator/converter. A stall safety shutoff

feature is built into the SECM to close the lock-off in

case of a stall condition. The SECM monitors three

engine states: Crank, when the crankshaft position

sensor detects any engine revolutions; Stall, when

the key is in the ON position but the crankshaft

position sensor detects no engine revolutions; and

the Run state, when the engine reaches pre-idle rpm.

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...