G424F(FE) Service Manual

Chapter 6. LPG FUEL DELIVERY SYSTEM

180

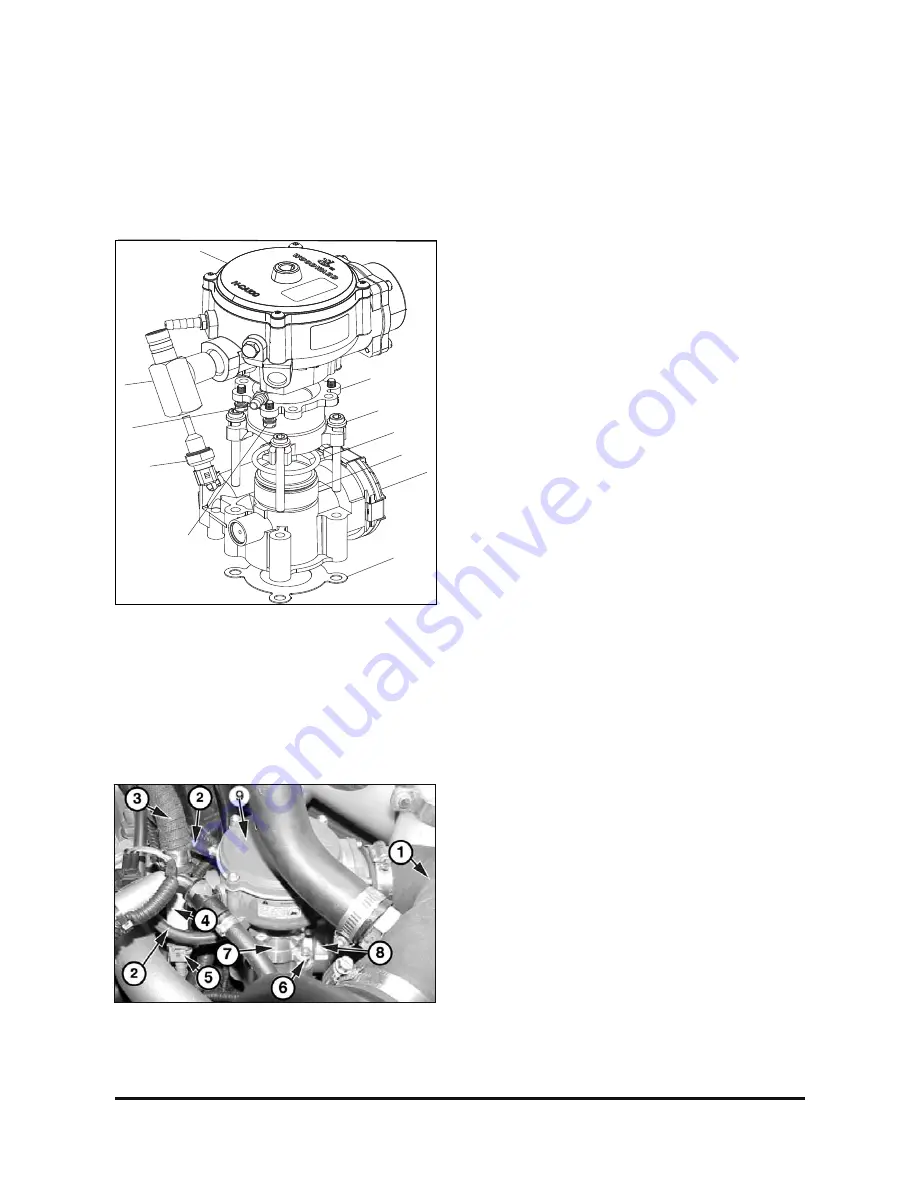

Removal and Installation of CA100 Mixer for

G424FE

Follow the procedures below for removal and

reinstallation of the CA100 mixer in certified systems.

CA100 Certified Mixer Removal Steps

5

8

7

9

10

11

3

4

2

1

6

1. Gasket-ITB

2. ITB

3. O-Ring

4. O-Ring Spacer

5. Mixer

6. Bolt

7. Fuel Temp Sensor

8. Adapter-Fuel Temp Sensor

9. Fitting-Vacuum Small

10. Apollo Adapter-ITB, Mixer

11. Bolt

Figure 30. CA100 Mixer in Certified System

1.

Close the liquid outlet valve in the forklift cylinder

or fuel storage container.

2.

Purge the system of fuel by starting the engine

and running until all trapped fuel in the system is

exhausted and the engine shuts down.

3.

Key switch in “OFF” position.

4.

Remove the air cleaner hose (1).

5.

Mark the two vacuum lines (2) to the mixer for

identification, as they must be reinstalled

correctly for proper operation. Remove the two

vacuum lines (2).

6.

Remove vapor fuel inlet line (3) from the fuel

temperature sensor fitting (4).

7.

Disconnect the fuel temperature sensor

connector (5).

8.

Disconnect the wires leading to the electronic

throttle body by pinching the lock tabs on either

side of the wiring harness connector. (See Figure

31 for location of connector)

9.

Loosen the four bolts (6) that secure the

mixer/adapter/throttle body assembly to the

intake manifold.

10.

Remove the mixer (9), the adapter (7), and the

throttle body (8) as an assembly by gently pulling

upwards. Take care not to drop anything down

the intake manifold.

11.

Gently wiggle and pull to separate mixer and

adapter from the throttle body. Take note of the

adapter orientation on the mixer, as it must be

reinstalled correctly for proper fit on the throttle.

12.

Remove the four mounting screws that attach the

throttle body adapter to the mixer.

13.

Remove the fuel temperature sensor (not shown)

from the tee (4).

14.

Remove the fuel temperature sensor fitting

from the mixer. Take note of the fitting’s

orientation on the mixer, as it must be

reinstalled correctly for proper fit.

15.

Remove the short vacuum port barb from the

mixer. (See

Figure 32

for location of port barb

on mixer.)

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...