G424F(FE) Service Manual

Chapter 6. LPG FUEL DELIVERY SYSTEM

199

AVV (Air Valve Vacuum) Testing

Purpose of Test

Check for excessive or inadequate pressure drop

across CA100 mixer.

AVV Test Hardware

1.

Union Tee fitting, 1/4” (6.35mm) NPT

with three 1/4” (6.35mm) NPT x 1/4” (6.35mm)

hose barbs

2.

Vacuum hose

3.

0-20” H2O differential pressure Magnehelic gauge

AVV Test

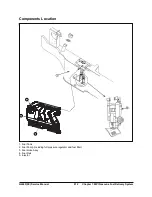

1.

Install Union Tee fitting in the hose between the

FTVs and the AVV fitting. Connect this fitting to

the low pressure port of the Magnehelic gauge

(Figure 37).

2.

Leave high pressure port of the Magnehelic

gauge exposed to ambient pressure (Figure 37).

3.

With the engine fully warmed up and running at

idle (750 rpm) place the transmission in Neutral.

The AVV should be between 5” and 8” H2O of

pressure vacuum.

4.

If the measured pressure drop is excessively high,

check for sticking or binding of the diaphragm air

valve assembly inside the mixer. Replace mixer if

necessary.

5.

If the measured pressure drop is low, check for

vacuum leaks in the manifold, throttle, mixer,

TMAP sensor and attached hoses.

Figure 37. Magnehelic Gauge Connection

Ignition Timing Adjustment

With the MI-07 system, ignition-timing advance is

controlled by the SECM.

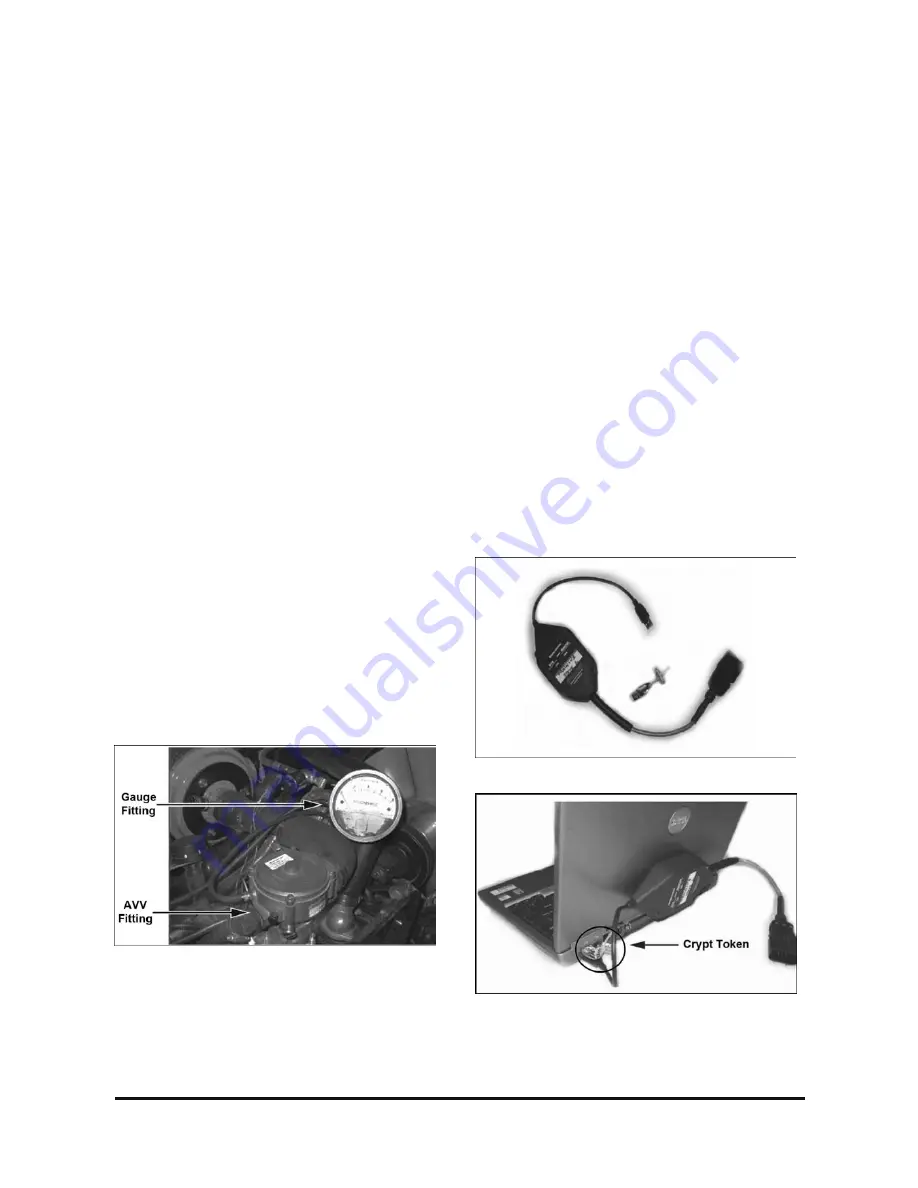

Connection of the MI-07 Service Tool

To use the Service Tool, a USB (Universal Serial

Bus) to CAN (Controller Area Network) communica-

tion adapter by KVaser will be required along with a

Crypt Token (Figure 38). The Crypt Token acts as a

security key allowing the laptop to retrieve the

necessary data from the SECM.

1.

Install the Crypt Token in an available USB port in

the computer (Figure 39).

2.

With the ignition key in the OFF position, connect

the KVaser communication cable from a second

USB port on the computer to the CAN

communications cable on the engine. (*If your

laptop computer does not have a second USB

port an appropriate USB hub will need to be used).

3.

Connect a timing light to the engine.

4.

Turn the ignition key to the ON position (Do Not

Start the Engine).

5.

Launch the MotoView program on your computer

and open the Service Tool display (Figure 40).

Figure 38. KVaser Communication Adapter

Figure 39. Crypt Token Installed on Laptop

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...