Power Train

Testing And Adjusting

27

Converter Stall Test

The converter stall test is a test to check engine

power. It can also be used to locate a problem in the

transmission when the condition of the engine is

known. An engine which does not have the correct

performance will give an indication of a stall speed

that is not correct. If the engine performance is

correct and the stall speed is not correct, the

problem in the converter or transmission can be

identified with this test.

The test checks the maximum RPM when the

engine, at full throttle, can turn the converter with the

turbine held stationary. To hold the converter turbine,

engage the brakes with the transmission in either

FORWARD or REVERSE.

The drive wheels must not turn during the stall test.

Put a heavy load on the forks and put the truck in

position against a solid object that will not move

(such as a loading dock). When the tests are made,

the wheel brakes must be engaged with the left foot

so that the accelerator pedal can be operated with

the right foot. Make sure that the transmission oil is

at the correct temperature for operation before tests

are made.

Check the high idle setting before the stall test is

made. Refer to the value of the next page.

WARNING

Make tests in a clear level area only. There must

be one operator. Keep all other personnel away

from the lift truck. Check the operation of the

brakes before the tests are made.

WARNING

In case of G20/25/30G model, the function of

ground speed control is equipped as the

standard configuration. So, if the ground speed

was modified in the field other than “ 2,450 +/- 50

rpm “, the high idle rpm should be changed to

this range with the engine service tool before

measuring the stall speed. After check and

repair, the ground speed needs to be returned to

the original range with the engine service tool.

1.

Connect a tachometer to the engine. start the

engine and move the control lever to the

FORWARD direction.

In case of G20/25/30G, a tachometer is not

required if the engine service tool is available and

connected.

2.

Engage the wheel brakes and push the

accelerator pedal down completely. Read the

RPM on the tachometer, then release the

accelerator pedal.

NOTICE

To make sure that the transmission oil does not get

hot, do not hold the transmission in a stall condition

for more than ten seconds. After the transmission is

stalled, put the controls in NEUTRAL and run the

engine at 1200 to 1500 RPM to cool the oil.

3.

Repeat the procedure above for the REVERSE

direction.

4.

The stall speed is as follows.

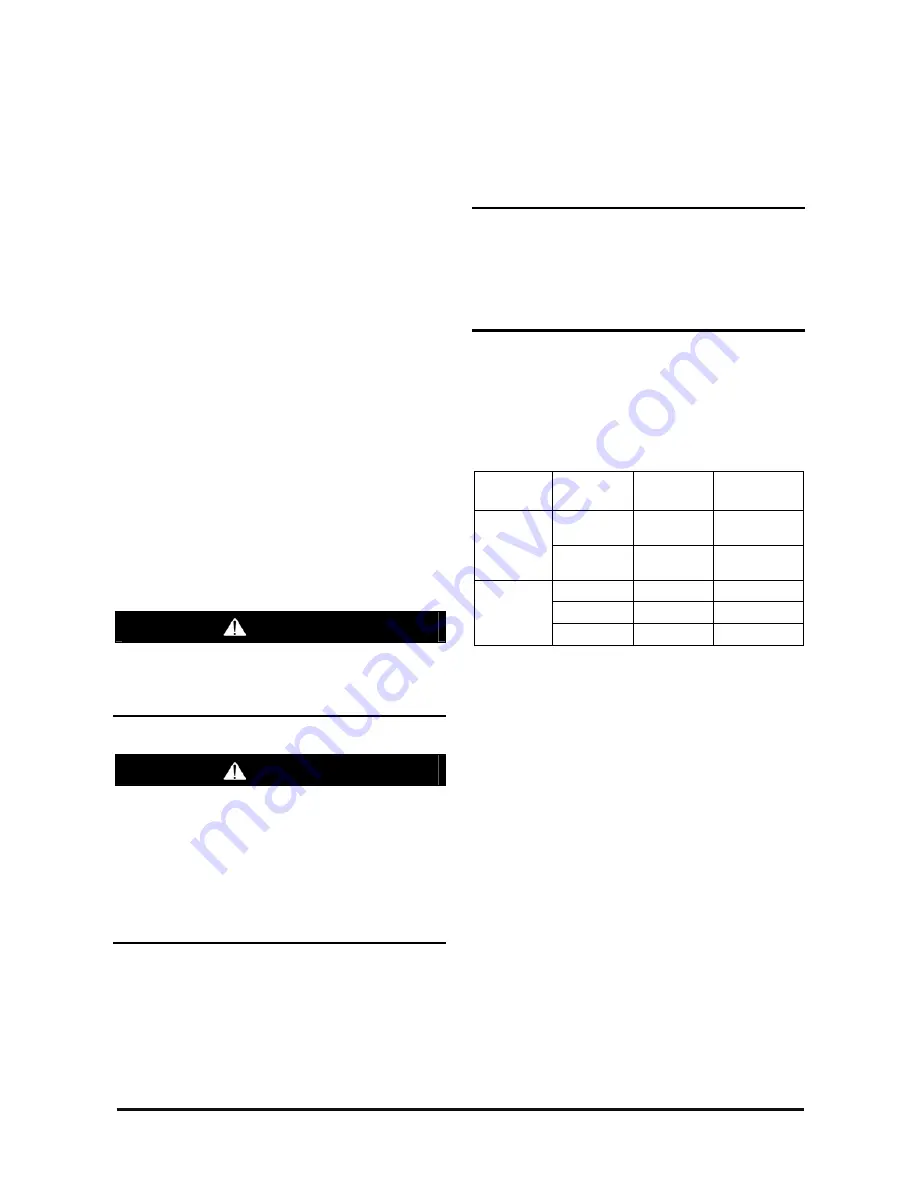

Stall Speed Chart

< Unit ; rpm >

Truck

model

Engine

High idle

Stall speed

D20/25/30G

Cummins

B3.3

2,470 +/- 50

1,950 +/- 75

Yanmar

4TNE98

2,625 +/- 50

2,137 +/- 100

G20/25/30G

G424F GAS

2,450 +/- 50

1.955 +/- 100

G424F LP

2,450 +/- 50

2,039 +/- 100

G424FE LP

2,450 +/- 50

2,142 +/- 100

Low stall speed is an indication that the engine

performance is not correct or the one-way clutch of

the torque converter does not hold in reverse

direction.

The stall speed must be the same in FORWARD

and REVERSE. If the stall speed is high in

FORWARD and / or REVERSE, check the

followings:

a.

Check out the air in the oil.

b.

Check the torque converter and the clutch

pressure.

c.

If clutch pressure is correct, make an inspection

of the clutch assembly of that direction for

possible damage to clutch components.

Summary of Contents for D20G

Page 2: ......

Page 5: ...Specifications TORQUE SPECIFICATIONS SB2004E00 D e c 1 9 9 8 ...

Page 14: ......

Page 16: ......

Page 138: ...Diesel Engine Engine System 124 NOTE The crankshaft must rotate freely by hand 02900058 ...

Page 254: ......

Page 256: ......

Page 260: ......

Page 341: ...4TNV98 4TNE98 Diesel Engine Section 3 Engine 87 4TNE98 Engine Figure 6 1 ...

Page 423: ...4TNV98 4TNE98 Diesel Engine Section 4 Fuel System 169 Fuel System Components Figure 7 1 ...

Page 477: ...4TNV98 4TNE98 Diesel Engine Section 7 Starter Motor 223 Starter Motor Troubleshooting ...

Page 494: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 240 Troubleshooting Charts ...

Page 495: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 241 ...

Page 496: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 242 ...

Page 498: ...4TNV98 4TNE98 Diesel Engine Section 8 Troubleshooting 244 4TNE98 Engine ...

Page 499: ...Service Manual G424FE LP Engine G424F LP Gasoline Engine G20G G25G G30G SB4320E00 Jan 2008 ...

Page 500: ......

Page 502: ......

Page 529: ...G424F FE Service Manual Chapter 2 Recommended Maintenance 29 ...

Page 534: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 34 MAIN BEARINGS 0 50 UNDERSIZE ...

Page 584: ...G424F FE Service Manual Chapter 3 Engine Mechanical System 84 ...

Page 729: ...G424F FE Service Manual 229 Chapter 8 Basic Troubleshooting ...

Page 731: ...G424F FE Service Manual 231 Chapter 8 Basic Troubleshooting ...

Page 806: ......

Page 808: ......

Page 810: ......

Page 820: ...Power Train System Operation 14 Hydraulic System ...

Page 822: ...Power Train System Operation 16 Hydraulic System ...

Page 824: ...Power Train System Operation 18 Hydraulic System ...

Page 826: ...Power Train System Operation 20 Hydraulic System ...

Page 856: ......

Page 858: ......

Page 860: ......

Page 930: ......

Page 932: ......

Page 934: ......

Page 936: ......

Page 1018: ......

Page 1023: ...A374081 01 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0K2 EM0K3 Cummins B3 3 ...

Page 1024: ...A654030 00 ELECTRIC SCHEMATIC MODEL D20 25 30G EM0QM EM0QN Yanmar 4TNE98 Tier 3 ...

Page 1025: ...A604500 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QF EM0QG GM G424F Non Certi LP ...

Page 1026: ...A604510 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QH EM0QJ GM G424F Non Certi GAS ...

Page 1027: ...A604516 00 ELECTRIC SCHEMATIC MODEL G20 25 30G EM0QY EM0QZ GM G424FE Tier 3 LP ...

Page 1028: ......

Page 1030: ......

Page 1059: ...Safety Section 29 Lean away from the direction of fall Lean forward ...

Page 1071: ...General Section 41 Typical Example Side Shifter Serial Number If Equipped ...