Operating & Maintenance Manual

DRAWBAR NOTICE

8

DRAWBAR NOTICE (Important)

This machine may have been shipped from

the factory with the drawbar positioned

upright.

To Convert From Shipping Position to

Towing Position

The following tools are required:

Ratchet

13mm socket to fit ratchet

Torque wrench set to 68 foot pounds (9.4 kg-

meters)

16mm socket to fit torque wrench

5 inch extension for torque wrench

Hardware Included:

(4) 12mm bolts with pre-applied thread lock

(2) 8mm Taptite Bolts

(2) Washers

(2) Safety Chains

1. Remove hardware box from compressor

toolbox.

2. Open box and remove the bag containing

hardware, safety chains and assembly

instructions.

3.Using the jack, raise the front of the unit so

that the legs are approximately 1” above the

ground.

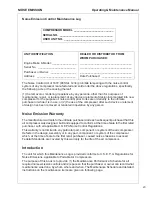

4.Remove the temporary retaining bolts from

both sides of the frame at the drawbar

connection (See Figure 1).

5.Carefully lower drawbar to the Level

Position.

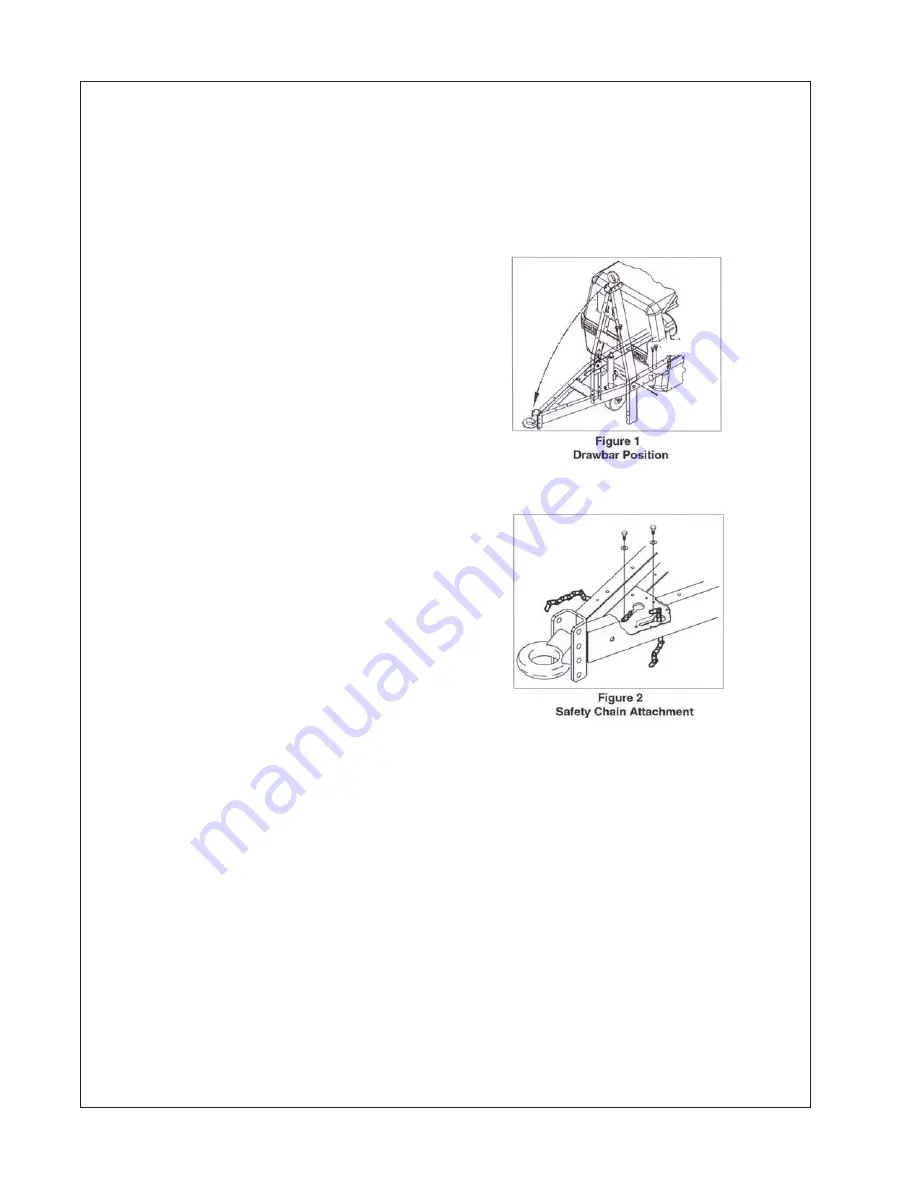

6.Install the four bolts (with pre-applied

thread lock) to the four points inside the

enclosure and torque to 68 ft. lbs.(9.4kg-m)

(See Figure 2).

7.Install safety chains by sliding the second

link of one chain into the slot in drawbar

plate. Fasten chain to plate using taptite and

washer. Repeat for the other chain (See

Sketch).

8. Temporarily support drawbar and move

jack from front of compressor to side of

drawbar.

Summary of Contents for D82

Page 2: ...2...

Page 5: ...3 FOREWORD...

Page 8: ...Operation Maintenance Manual FOREWORD 6...

Page 9: ...7 DRAWBAR NOTICE...

Page 11: ...DRAWBAR NOTICE Operating Maintenance Manual 9...

Page 12: ...Operating Maintenance Manual DRAWBAR NOTICE 10...

Page 13: ...11 SAFETY...

Page 16: ...Operating Maintenance Manual SAFETY 14...

Page 18: ...Operating Maintenance Manual SAFETY 16...

Page 19: ...SAFETY Operating Maintenance Manual 17...

Page 21: ...SAFETY Operating Maintenance Manual 19...

Page 23: ...21 NOISE EMISSION...

Page 29: ...27 GENERAL DATA...

Page 32: ...Operating Maintenance Manual GENERAL DATA 30...

Page 33: ...31 OPERATION...

Page 43: ...41 LUBRICATION...

Page 45: ...43 MAINTENANCE...

Page 55: ...53 TROUBLESHOOTING...