Operating & Maintenance Manual

MAINTENANCE

46

Tires

A weekly inspection is recommended. Tires that have cuts or cracks or little tread should be

repaired or replaced. Monthly check the wheel lug nuts for tightness.

Fasteners

Visually check entire unit in regard to bolts, nuts and screws being properly secured. Spot

check several capscrews and nuts for proper torque. If any are found loose, a more thorough

inspection must be made. Take corrective action.

Table 1:

Radiator

NOTICE

The use of water alone in this engine can result in major engine failure.

Refer to engine section for coolant recommendation.

Hoses

Each month it is recommended that all of the intake lines to and from the air cleaners, the

engine cooling system hoses and all of the flexible hoses used for air, oil, and fuel be

inspected.

To ensure freedom from air leaks, all rubber hose joints and the screw-type hose clamps must

be absolutely tight. Regular inspection of these connections for wear or deterioration is

necessary.

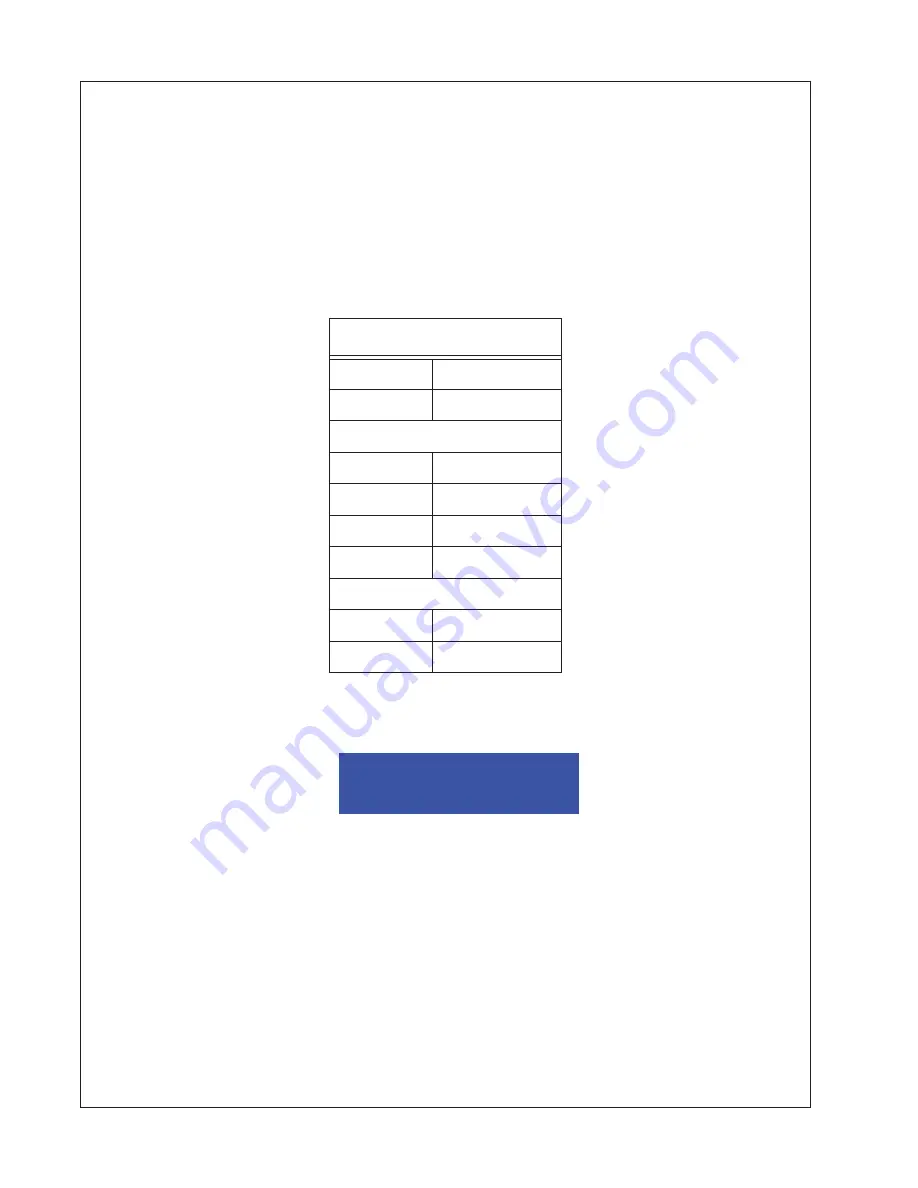

Wheel Torque Chart

M12 bolts

Torque (ft-lbs)

13” wheel

60-70

1/2” lug nuts

13” wheel

80-90

15” wheel

105-115

16” wheel

105-115

16.5 wheel

105-115

5/8” lug nuts

16” wheel

190-210

17.5” wheel

190-210

Summary of Contents for D82

Page 2: ...2...

Page 5: ...3 FOREWORD...

Page 8: ...Operation Maintenance Manual FOREWORD 6...

Page 9: ...7 DRAWBAR NOTICE...

Page 11: ...DRAWBAR NOTICE Operating Maintenance Manual 9...

Page 12: ...Operating Maintenance Manual DRAWBAR NOTICE 10...

Page 13: ...11 SAFETY...

Page 16: ...Operating Maintenance Manual SAFETY 14...

Page 18: ...Operating Maintenance Manual SAFETY 16...

Page 19: ...SAFETY Operating Maintenance Manual 17...

Page 21: ...SAFETY Operating Maintenance Manual 19...

Page 23: ...21 NOISE EMISSION...

Page 29: ...27 GENERAL DATA...

Page 32: ...Operating Maintenance Manual GENERAL DATA 30...

Page 33: ...31 OPERATION...

Page 43: ...41 LUBRICATION...

Page 45: ...43 MAINTENANCE...

Page 55: ...53 TROUBLESHOOTING...