15

DBC 130II

DBC130II ISE41

3. Transportation

The boring machine can be dismantled into each unit to facilitate the transportation of the

machine to the plant.

Since each one of the units is heavy weighted and unbalanced, pay attention to keep every

unit balanced if using a forklift or crane for transporting purpose.

(1) When the machine is delivered on site, check if every one of the units are all included in

the package based on the packing list.

(2) Use the crane or forklift to move the unit while keeping an eye on the balance.

(3) In this process, take caution lest that the wire rope or shackles should impact on the

unit, and adjust the length of the rope as appropriate to prevent it from being

unbalanced.

(4) If the rope is short, it may cause an interference with brackets or covers. This is why

you must pay special attention to the rope length.

Assembly

Weight

Unit

Remark

1 Table Ass’y

17,000Kg Table Bed, Rotary Table, Rotary Base

2 Column Bed Ass’y

11,000Kg Column Bed, Column Base

3 Column Body Ass’y

6,000Kg Column Body

4 Spindle Head Ass’y

2,500Kg Spindle Head

5 ATC Ass’y

3,000Kg ATC, Tool Magazine, Tool Magazine Base

6 Others

3,500Kg Electric Cabinet, Hydraulic Unit, Oil

Cooler, Duct & Covers, Chip Conveyor

and Accessories

Total weight of machine

43,000Kg

The above list is for the standard equipment, and is subject to change without notice for

reasons of customer specifications or engineering changes.

※

Precautions for lifting up the assembly

1) Ensure that the front/rear sides of the table bed (X axis) and the left/right sides of the

column bed (Z axis) are fixed by the factory default brackets.

(2) Before lifting up the table bed and column bed units, hook wire ropes between eyebolts

in the sides of the bed and crane. To prevent the machine from being damaged, wrap

the contact points between ropes and machine with pieces of wood or cloth.

(3) When lifting up the column body, stretch the rope as appropriate for avoiding a possible

interference with the glass scale.

(4) In order to lift up the table bed and column bed units at once, you must use a crane

weighing at least 20 tons. (Required specifications: 20 tons of weight and 8m of tensile

height)

Summary of Contents for DBC 130 II

Page 1: ...Installation Manual DBC 130Ⅱ Machine Tools ...

Page 2: ......

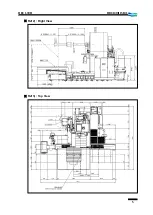

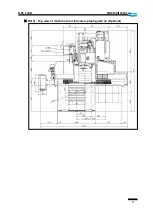

Page 7: ...5 DBC 130II DBC130II ISE41 Ref 2 Right View Ref 3 Top View ...

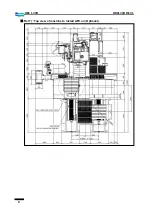

Page 9: ...7 DBC 130II DBC130II ISE41 Ref 6 Top view of machine to install semi splash guard on Optional ...

Page 10: ...8 DBC 130II DBC130II ISE41 Ref 7 Top view of machine to install APC on Optional ...

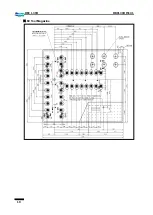

Page 12: ...10 DBC 130II DBC130II ISE41 60 Tool Magazine ...

Page 60: ...58 DBC 130II DBC130II ISE41 Z axis ...

Page 121: ...119 DBC 130II DBC130II ISE41 19 Installation Complete ...