4

DBC 130II

DBC130II ISE41

1. Installation Site

1) Do not install the machine in a place of a high temperature difference or in areas that are

exposed to dust or direct sunlight, and consider the ventilation condition. Besides, it is

recommended to select a place of less vibration. However, if it's inevitable, take

appropriate actions (reinforced foundation, reinforced ground, and dustproof screen, etc)

to prevent the machine from being affected by the vibration .

2) The minimum bearing power of soil that is required to install the machine is 10 tons/m².

3) A 20-ton crane with a lifting performance of 8m must be equipped at the installation site.

The installation personnel should take into consideration the dynamic relation between

crane and foundation.

▪

If a crane meeting the above specification is not available, use alternatives such as a

car crane, large forklift, etc., for moving the machine.

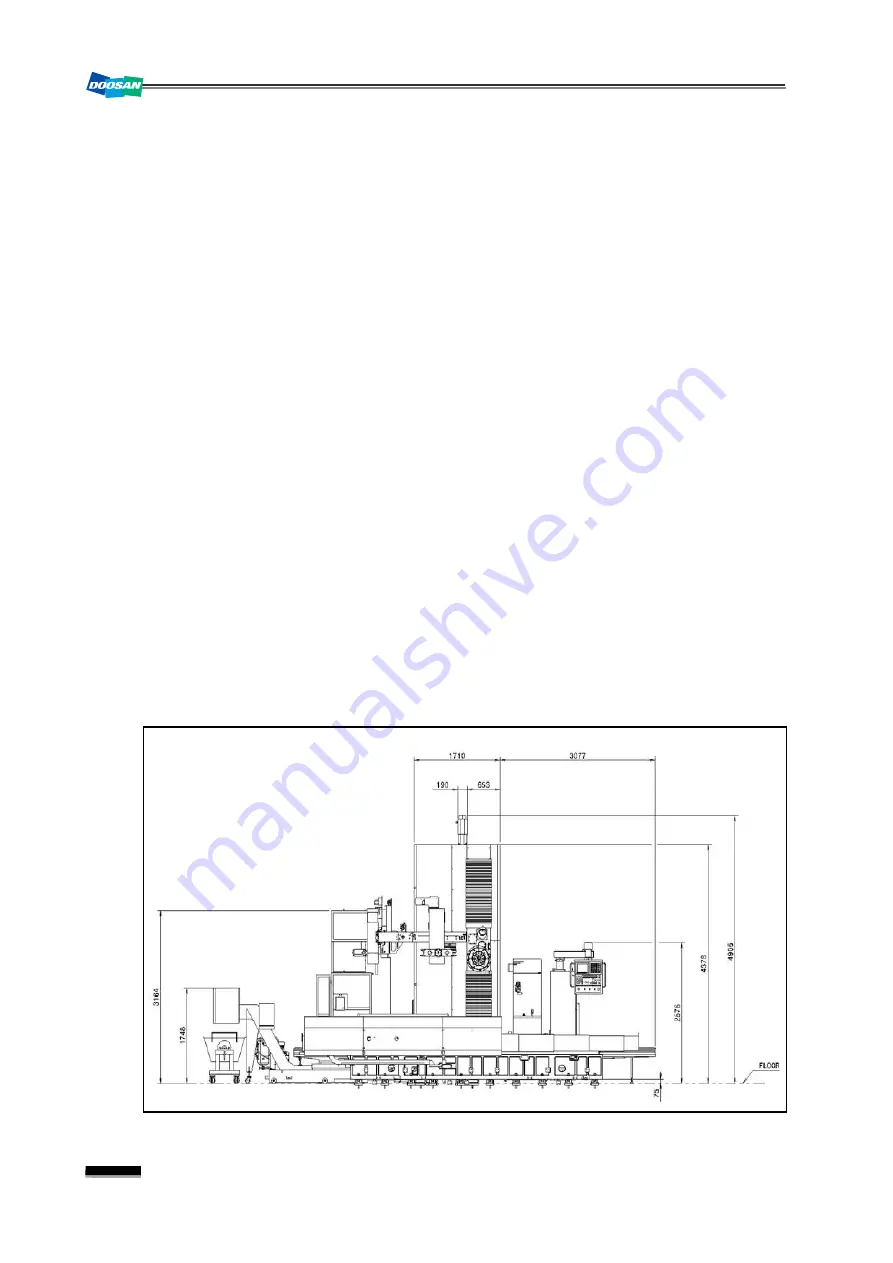

4) When determining the installation site, refer to the machine layout diagram to secure

room for installing the assemblies (ATC,

electric cabinet, hydraulic tank, chip conveyor,

etc) as well as enough room for repair (so that the doors are open/closed without

interruption). Besides, secure enough room between machines to facilitate the

installation work of the chip conveyor.

5) Refer to the layout diagram below.

(For reference Only)

※

The below diagram is a standard machine layout for reference. The actual layout may

differ due to engineering changes or application of client specifications. Refer to the

layout diagram that is specific to the machine to install.

※

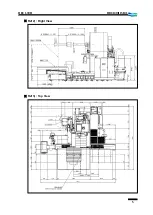

Ref 1) : Front View

Summary of Contents for DBC 130 II

Page 1: ...Installation Manual DBC 130Ⅱ Machine Tools ...

Page 2: ......

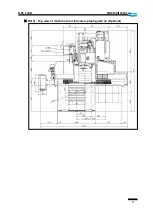

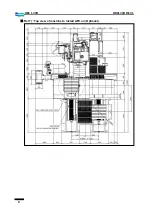

Page 7: ...5 DBC 130II DBC130II ISE41 Ref 2 Right View Ref 3 Top View ...

Page 9: ...7 DBC 130II DBC130II ISE41 Ref 6 Top view of machine to install semi splash guard on Optional ...

Page 10: ...8 DBC 130II DBC130II ISE41 Ref 7 Top view of machine to install APC on Optional ...

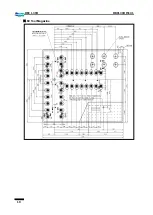

Page 12: ...10 DBC 130II DBC130II ISE41 60 Tool Magazine ...

Page 60: ...58 DBC 130II DBC130II ISE41 Z axis ...

Page 121: ...119 DBC 130II DBC130II ISE41 19 Installation Complete ...