80

DBC 130II

DBC130II ISE41

15.2 Straightness of X Axis

1) X - Y

2) Y - Z

ⓐ

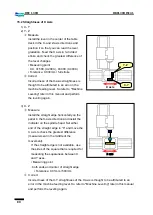

Measure

Install the level in the center of the table

deck in the X- and Z-axis directions and

position it so that you can read the level

gradation. Feed the X axis in 3-divided

stroke and check the greatest difference of

the level changes.

▪

Measuring point

: X0., X1500. (X2000.), X3000. (X4000.)

▪

Tolerance: 0.030mm / full stroke

ⓑ

Correct

Incorrectness of the X-axis straightness is

thought to be attributed to an error in the

machine feeding level. So refer to "Machine

Leveling" later in this manual and perform

the leveling again.

3) X - Z

ⓐ

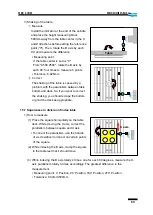

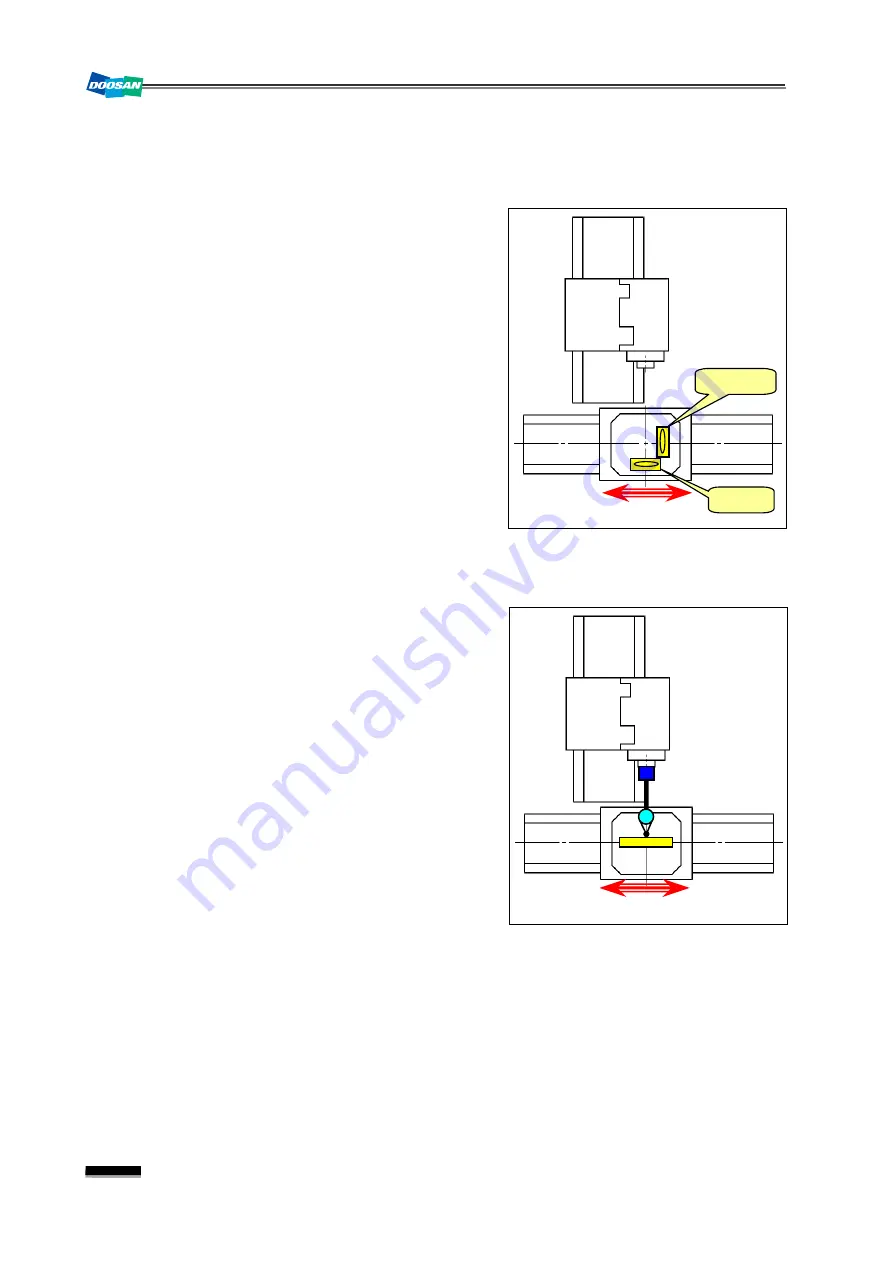

Measure

Install the straight edge horizontally on the

pallet in the X-axis direction and install the

indicator on the spindle head. Set either

end of the straight edge to “0” and move the

X axis to check the greatest difference

(measurement in the middle of the

movement).

※

If the straight edge is not available, use

the sides of the square that is required for

measuring the squareness between X

and Y axes.

▪

Measuring point

: both ends and center of straight edge

▪

Tolerance: 0.01mm / 500mm

ⓑ

Correct

Incorrectness of the X-Y straightness of the X axis is thought to be attributed to an

error in the machine feeding level. So refer to "Machine Leveling" later in this manual

and perform the leveling again.

Y-Z

X axis

X-Y

X axis

Summary of Contents for DBC 130 II

Page 1: ...Installation Manual DBC 130Ⅱ Machine Tools ...

Page 2: ......

Page 7: ...5 DBC 130II DBC130II ISE41 Ref 2 Right View Ref 3 Top View ...

Page 9: ...7 DBC 130II DBC130II ISE41 Ref 6 Top view of machine to install semi splash guard on Optional ...

Page 10: ...8 DBC 130II DBC130II ISE41 Ref 7 Top view of machine to install APC on Optional ...

Page 12: ...10 DBC 130II DBC130II ISE41 60 Tool Magazine ...

Page 60: ...58 DBC 130II DBC130II ISE41 Z axis ...

Page 121: ...119 DBC 130II DBC130II ISE41 19 Installation Complete ...