OP000599

4-69

Inspection, Maintenance and Adjustment

BUCKET

Bucket Tooth Replacement

NOTE:

These instructions are only for DOOSAN OEM

buckets. If you are using other manufacturers

buckets, refer to their specific instructions.

1.

On a routine basis, inspect bucket teeth to make sure that

tooth wear or breakage has not developed. Do not allow

replaceable bucket teeth to wear down to a point that

bucket adapter is exposed. See Figure 126.

2.

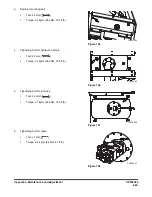

To replace a tooth (1, Figure 127), use a hammer and

punch to drive locking pin (2) and lock washer (3) out of

tooth adapter (4).

3.

Once worn tooth has been removed, use a putty knife to

scrape adapter as clean as possible.

4.

Slide new tooth into position and insert lock washer.

5.

Insert locking pin into tooth and with a hammer, drive pin in

until lock washer seats in locking groove.

WARNING!

Due to the possibility of flying metal objects, always wear

safety helmet, protective gloves and eye protection when

changing bucket teeth.

Curl the bucket upwards and place the round rear surface

of the bucket firmly on the ground. Shut the engine off and

lock out the hydraulic controls before working on the

bucket.

HAOC680L

Figure 126

2

4

3

FG000346

1

Figure 127

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...