OP000599

Inspection, Maintenance and Adjustment

4-84

VENTING AND PRIMING

HYDRAULIC SYSTEM

Main System Pump

NOTE:

If pump is run without sufficient oil in the main

hydraulic pump, damage can occur. Always vent

pump of air after draining hydraulic system.

1.

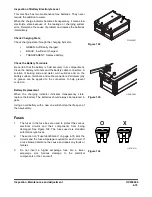

With the engine stopped, remove vent plug (Figure 143) to

see if any oil is present.

2.

If oil is not present, fill pump with oil through port (Figure

143).

3.

Install vent plug (Figure 143) first.

4.

Start engine and run it for several minutes at low idle

engine speed. This will pressurize the hydraulic oil tank

and system.

5.

Slowly loosen vent plug (Figure 143) several turns, until

hydraulic oil flows out of plug. This shows that air has been

released.

6.

Tighten the plug (Figure 143).

Hydraulic Cylinders

1.

Run engine at low idle. Extend and retract each cylinder to

within 100 mm (4 in) of fully stroking it 4 - 5 times.

2.

Operate fully extend and retract each cylinder 3- 4 times.

3.

Repeat procedure until cylinders extend and retract

smoothly.

Figure 143

FG009595

IMPORTANT

If cylinders are operated in high idle after the hydraulic

system has been drained or the cylinder has been rebuilt,

damage to piston packing and seals may occur. Always

vent air from cylinders at low idle and at a slow speed.

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...