OP000599

Inspection, Maintenance and Adjustment

4-46

Replace Hydraulic Oil Return Filter

NOTE:

Change hydraulic oil return filter after first 250 hours

of operation or rebuild, and every 1,000 hours

thereafter.

NOTE:

If return filter clogged warning light (Figure 75) on

instrument panel comes "ON" the return filter must be

serviced.

1.

Position the machine on firm, level ground. Lower the front

attachment to the ground and shut down engine.

2.

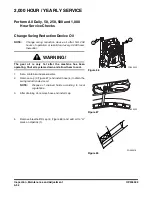

Loosen the breather cap (1, Figure 76) slightly to release

the internal pressure.

3.

Remove bolts (2, Figure 76) and service cover (3).

Remove spring (4), valve (5) O-ring (6), and bypass

strainer (7), and then filter (8).

4.

Remove filter and discard.

NOTE:

Used filter should always be disposed of

according to local regulations.

5.

Install new filter and a new O-ring. Install bypass strainer,

valve and spring. Install service cover plate.

6.

Tighten the breather cap (1, Figure 76).

7.

Run engine for ten minutes at low idle to purge air from

circuit.

8.

Check level in hydraulic oil tank (See page 4-15). Add oil if

necessary.

Figure 75

C

H

C

E

F

H

E/G SPEED

1700

RPM

FG000760

02/05 [MO] 11:30

1

3

2

FG009577

Figure 76

WARNING!

The hydraulic oil will be hot after normal machine

operation. Allow the system to cool before attempting to

service any of the hydraulic components.

The hydraulic tank is pressurized. Loosen the hydraulic

breather cap slightly to allow the pressurized air to vent.

After the pressure has been released, it is safe to remove

either the fill cap or service covers or drain water from the

tank.

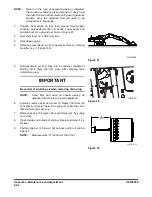

Figure 77

7

5

8

4

3

6

FG000761

IMPORTANT

Make sure to clean any dirt or water from the top of the

hydraulic tank, especially around the fill port and filter

ports.

Summary of Contents for DX140LC

Page 2: ......

Page 67: ...OP000597 2 3 Operating Controls ...

Page 87: ...OP000597 2 23 Operating Controls ...

Page 122: ...OP000597 Operating Controls 2 58 CD Player Optional AST DIR FG000109 Figure 123 ...

Page 184: ...OP000598 Operation 3 48 ...

Page 193: ...OP000599 4 9 Inspection Maintenance and Adjustment ...

Page 272: ...OP000599 Inspection Maintenance and Adjustment 4 88 ...

Page 278: ...OP000600 Transportation 5 6 ...

Page 284: ...OP000013 Troubleshooting 6 6 ...

Page 292: ...OP000601 Specification 7 8 ...