OP000530

Inspection, Maintenance and Adjustment

4-28

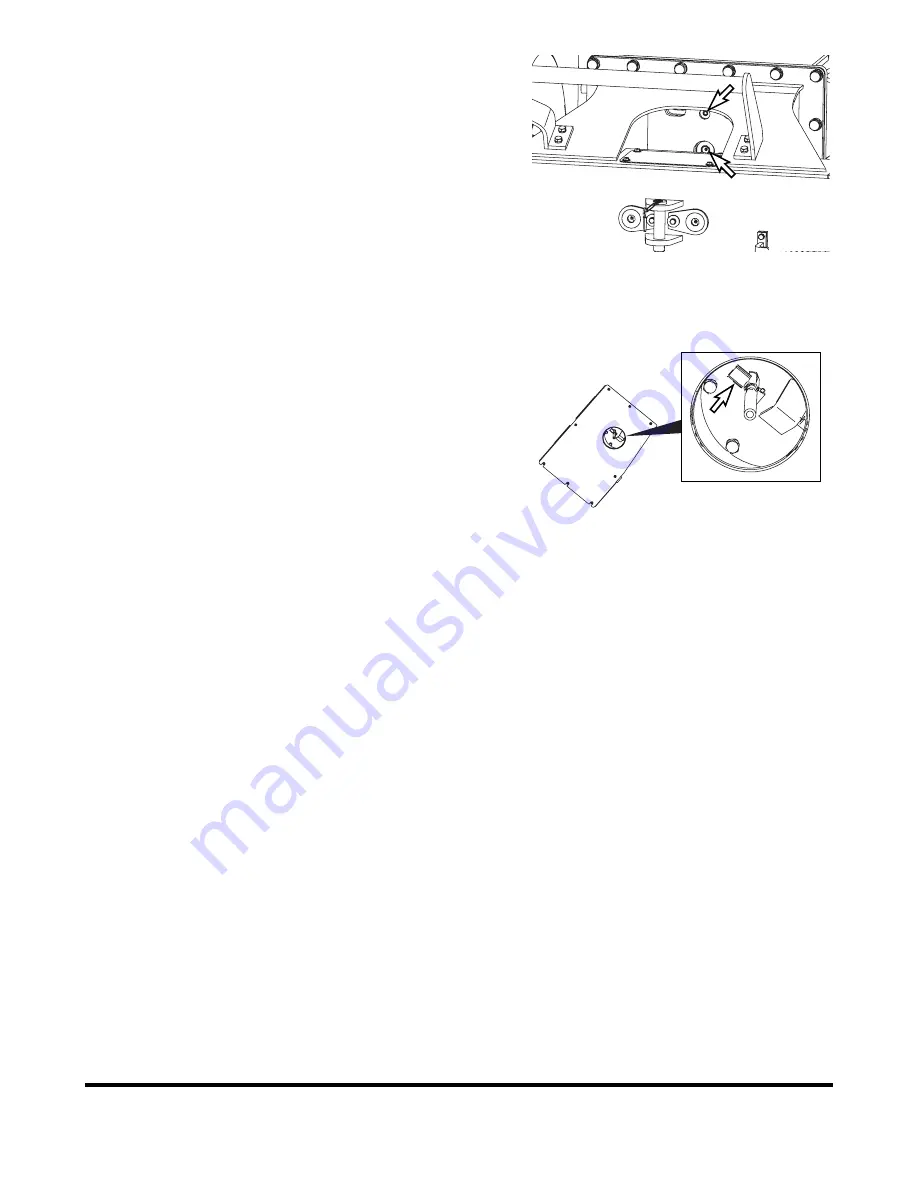

Grease Front Axle Pin

NOTE:

If the unit has been running or working in water the

front attachment should be greased on a 10 hour /

daily basis.

1.

Lower the front attachment to ground.

2.

Press the grease fitting and inject grease with the grease

gun on the marked point.

3.

After injection, clean off the old grease that has been

purged.

Drain Water and Sediment from Fuel Tank

1.

Perform this procedure before operating the machine.

2.

Drain water and sediment from bottom of fuel tank into a

suitable container.

NOTE:

Dispose of drained fluid according to local

regulations.

NOTE:

Always completely fill fuel tank at end of each

workday to prevent condensation from forming

on the inside walls of the tank.

Check Engine Fan Belt for Cracks, Wear

and Correct Tension (After First 50

Hours)

1.

Inspect after first 50 hours of operation and every 150

hours thereafter. (See page 4-28)

Change Engine Oil and Filter (After First 50

Hours)

1.

Change engine oil and filter after first 50 hours of operation

or rebuild, then every 150 thereafter. (See page 4-28)

Inspect for Any Loose or Missing Nuts and

Bolts

1.

All nuts and bolts must be inspected after first 50 hours of

operation. There after every 250 hours.

FG006632

Figure 41

Figure 42

FG006633

Summary of Contents for DX190W

Page 2: ......

Page 71: ...OP000528 2 3 Operating Controls ...

Page 128: ...OP000528 Operating Controls 2 60 CD Player Optional AST DIR FG000109 Figure 135 ...

Page 196: ......

Page 292: ...OP000530 Inspection Maintenance and Adjustment 4 96 ...

Page 304: ...OP000440 6 8 Troubleshooting ...