DX380LC-7

Safety

1-24

Fueling

Use caution when you are refueling a machine.

Fuel is flammable and can catch fire if it is brought close to a

flame.

Stop engine and let it cool before adding fuel. Do not smoke

while you are refueling a machine. Do not refuel a machine near

flames or sparks. Fill fuel tank outdoors.

Keep fuel and other fluid reservoir caps tight and do not start

engine until caps have been secured.

Store fuels and lubricants in properly marked containers away

from unauthorized personnel. Store oily rags and any flammable

materials in protective containers.

Static electricity can produce dangerous sparks at fuel filling

nozzle. In very cold, dry weather or other conditions that could

produce a static discharge, keep tip of fuel nozzle in constant

contact with neck of fuel filling nozzle, to provide a ground.

Always place plastic fuel containers on the ground before filling.

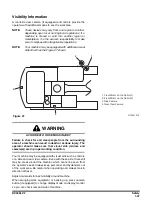

Never Use Ether Starting Aids

Do not use ether or starting fluids on any engine that has glow

plugs, or an electric grid type manifold heater. These starting

aids can cause an explosion and result in death or serious

injury.

Use procedures in this manual for connecting battery and for

jump-starting.

Welding and Grinding

Always clean machine and attachment, set battery disconnect

switch to "OFF" position, and disconnect wiring from electronic

controllers before welding. Cover rubber hoses, battery and all

other flammable parts. Keep a fire extinguisher near machine

when welding.

Toxic dust or gas can be produced when grinding or welding

painted parts. Grinding or welding painted parts must be done in

a well ventilated area. Wear dust mask when grinding painted

parts.

Dust generated from repairing nonmetallic parts such as hoods,

fenders or covers can be flammable or explosive.

Repair such components in a well ventilated area away from

flames or sparks.

Do not weld on lines or on tanks that contain flammable fluids.

Do not flame cut lines or tanks that contain flammable fluid.

Clean any such lines or tanks thoroughly with a nonflammable

solvent before welding or flame cutting.

EX1400130

Figure 14

Figure 15

FG018458