3-23

DX380LC-7

Manual (Forced) Regeneration

The regeneration is manually (forced) activated by the operator

when the operator chooses to start the regeneration process.

Manual (forced) regeneration may be required if the operator

"inhibits" the active regeneration process for an extended period

of time because the operating conditions are not favorable to hot

engine exhaust temperatures (e.g. working near flammable

materials).

Procedures for manual (forced) regeneration by the operator.

1.

Park machine in a well ventilated area and away from

flammable materials.

2.

Set up machine in the following manner:

A.

Operate machine until engine coolant are above

40°C (104°F).

B.

Set engine speed to "LOW IDLE".

C.

Put transmission lever in "NEUTRAL" and engage

parking brake (Wheel excavator only).

3.

Move safety lever to "LOCK" position.

4.

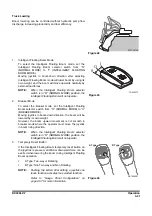

Activate regeneration switch (Figure 25) to start

regeneration process.

NOTE:

Regeneration light on monitor will be "ON".

NOTE:

Regeneration switch should be pushed 3 - 8 sec

for regeneration.

If puch time is over 16 sec, fault code would be

displayed on monitor.

Engine speed will gradually increase from "LOW IDLE" to

1,500 rpm and regeneration process will then start.

During regeneration, high temperature warning light will be

"ON".

When regeneration stops, regeneration and high temperature

warning lights will turn "OFF".

NOTE:

Operator can stop manual (forced) regeneration

by raising safety lever to "UNLOCK" position.

FG018280

O

I

II

Figure 25