DX380LC-7

Inspection, Maintenance and Adjustment

4-26

Hydraulic Oil Level - Check

1.

Park machine on firm and level ground. Lower boom and

position bucket on ground as shown in Figure 8.

2.

Move engine speed to "LOW IDLE".

3.

Move safety lever to "LOCK" position.

4.

Have a second person, check hydraulic oil level gauge by

opening right access door. Oil level must be between

marks on sight gauge.

5.

If the level is below "L" mark add oil.

A.

Stop engine.

B.

The hydraulic tank is pressurized. Tip breather cap

up slowly to allow the pressurized air to vent.

C.

Remove upper cover of the hydraulic tank and add oil.

ARO1760L

Figure 7

WARNING

AVOID DEATH OR SERIOUS INJURY

The hydraulic oil will be hot after machine operation. Allow

system to cool before attempting to service any hydraulic

components.

The hydraulic tank is pressurized. Tip breather cap up

slowly to allow the pressurized air to vent. After the

pressure has been released, remove service covers.

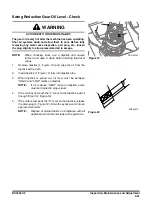

Figure 8

EX1300541

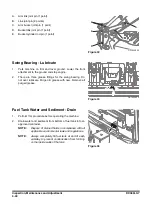

Figure 9

FG020182

H

L

DS1900831

Figure 10

NOTICE

Do not fill above "H" mark on sight gauge. Overfilling

can result in damage to equipment and oil leaking

from hydraulic tank because of expansion.