Inspection, Maintenance and Adjustment

4-57

DX380LC-7

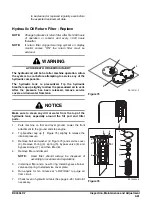

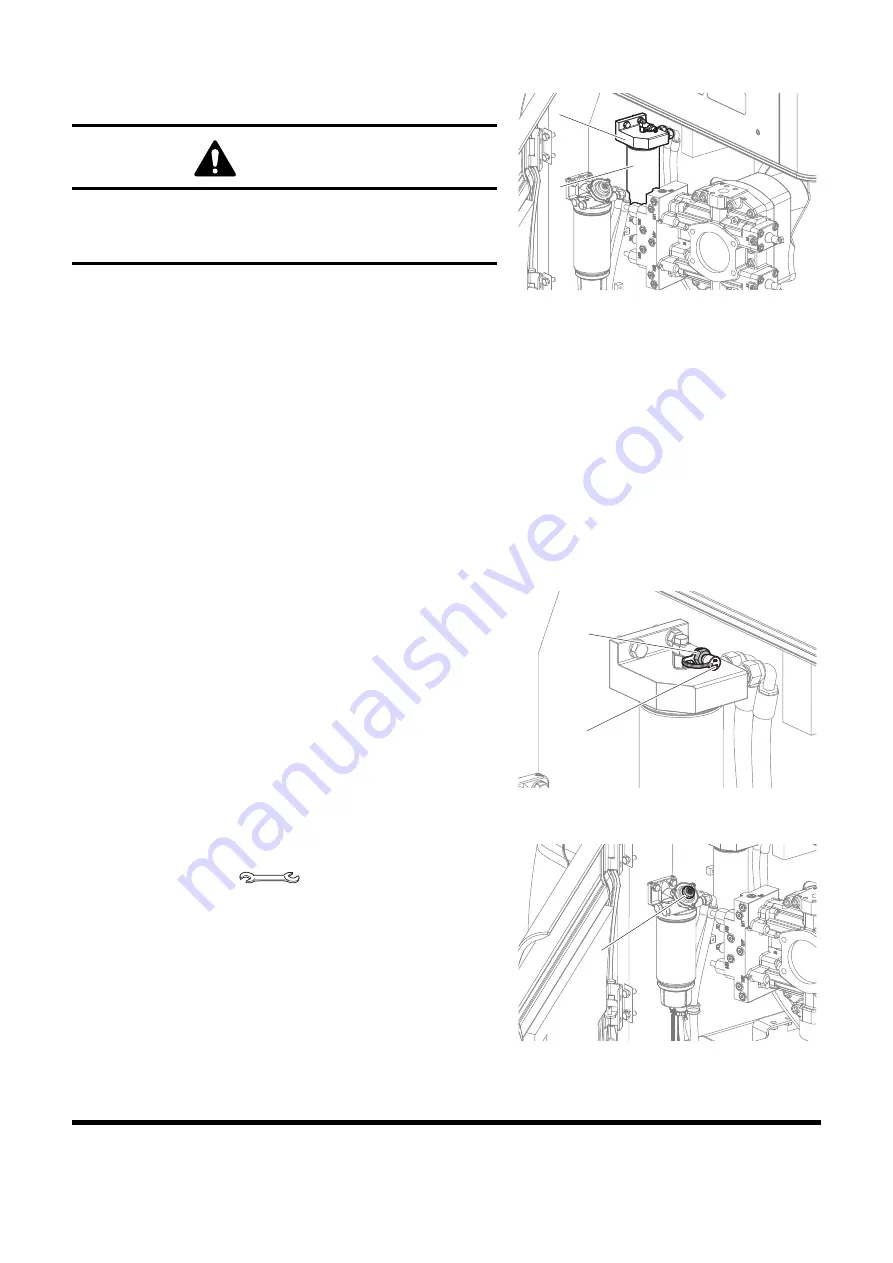

Main Fuel Filter - Replace

1.

Locate fuel filter inside pump compartment.

2.

Turn cock valve to "CLOSE" position. (Figure 65)

3.

Position a small container under fuel filter.

4.

Remove the fuel filter (1, Figure 65) from the fuel filter head

side (2, Figure 65) and discard properly.

NOTE:

Dispose of drained fluids in compliance with all

applicable environmental regulations.

5.

Fill two-thirds of the new fuel filter with clean fresh diesel

fuel and mount it using a filter wrench.

NOTE:

Coat fuel filter gasket with fuel.

NOTE:

Fill fuel filter with clean fuel. This will help

reduce fuel system priming.

Bleeding Fuel System

If air remains in the fuel inlet line to the engine, it can cause the

engine to run in an abnormal condition. Air may impact the

starting capability of the engine, and may also result in surging

engine speeds.

If the machine happens to have run out of fuel or the fuel filter

has been replaced and engine doesn’t start at a time after long-

term storage, bleed the air out using the following procedure:

1.

Stop Engine.

2.

Check cock valve (Figure 65) is open.

3.

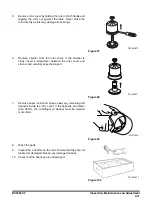

Remove the rubber cap (1, Figure 68) on the fuel filter head.

4.

Turn the air discharge nut (2, Figure 68).

•

Tool: 17 mm (

)

5.

Pump the pre-filter head (3, Figure 69) by hand until fuel

seeps out of the air discharge nut (2, Figure 68).

6.

When fuel seeps out, tighten the air discharge nut (2,

Figure 68) and reinstall the rubber cap (1, Figure 68).

7.

Start engine and look for signs of leaks.

8.

Repeat procedure if necessary.

DS1901879

2

2

2

1

1

Figure 67

WARNING

AVOID DEATH OR SERIOUS INJURY

Change filter after waiting for engine to cool. Be careful of

fire hazards. Do not smoke.

DS1901880

2

2

2

1

1

Figure 68

DS1901881

3

3

Figure 69