1-32

Precautions for Operation

Be careful not to go close to the edge of a cliff by mistake.

Use the machine only for its main purpose. Using it for other

purposes will cause failures.

To ensure an ample view, do as follows:

•

When working in dark areas, attach working lights

and front lights to the machine. If necessary, set up

lighting at the work site.

•

Stop operations when the visibility is poor, such as in

fog, mist, snow, and rain. Wait for the visibility to

improve to a level which causes no problems for the

operation.

To avoid hitting the work equipment, always do the following;

•

When working in tunnels, on bridges, under electric

wires, or when parking the machine or carrying out

other operations in places with limited height, be

extremely careful not to hit the bucket or other parts.

•

To prevent collisions, operate the machine at a safe

speed when working in confined spaces, indoors, or

in crowded areas.

•

Do not pass the bucket over the heads of workers or

over the operator's compartment of dump truck.

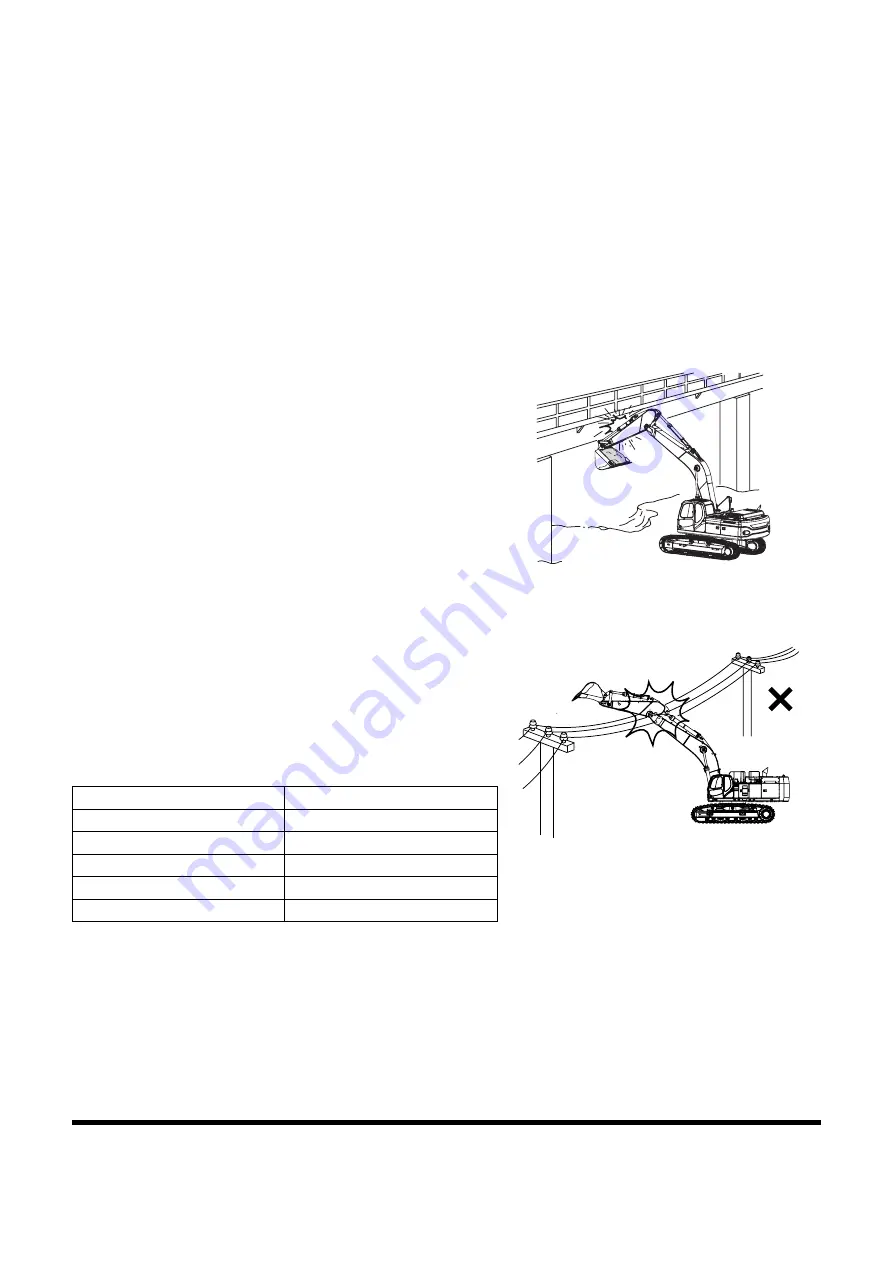

Avoid High Voltage Cables

Serious injury or death can result from contact or proximity to

high voltage electric lines. The bucket does not have to make

physical contact with power lines for current to be transmitted.

Use a spotter and hand signals to stay away from power lines

not clearly visible to the operator.

Use these minimum distances as a guideline only. Depending

upon the voltage in the line and atmospheric conditions, strong

current shocks can occur with the boom or bucket as far away

as 4 - 6 m (13 - 20 ft.) from the power line. Very high voltage and

rainy weather could further decrease that safety margin.

NOTE:

Before starting any type of operation near power lines

(either above ground or buried cable type), you

should always contact the power utility directly and

work out a safety plan with them.

Figure 23

FG000430

Figure 24

FG015758

Voltage

Minimum Safe Distance

6.6 kV

3 m (9' 10")

33.0 kV

4 m (13' 1")

66.0 kV

5 m (16' 5")

154.0 kV

8 m (26' 3")

275.0 kV

10 m (32' 10")

Summary of Contents for DX700LC

Page 2: ......

Page 72: ...OP001120 Safety 1 66 ...

Page 142: ...OP001121 Operating Controls 2 70 ...

Page 188: ...OP001122 Operation 3 46 ...

Page 197: ...OP001123 4 9 Inspection Maintenance and Adjustment ...

Page 282: ...OP001123 Inspection Maintenance and Adjustment 4 94 ...

Page 298: ...OP000030 Troubleshooting 6 6 ...

Page 301: ...OP001125 7 3 Specification ...

Page 308: ...OP001125 Specification 7 10 ...

Page 314: ...950106 00012E Index 8 6 ...