Inspection, Maintenance and Adjustment

4-30

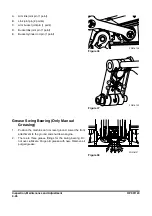

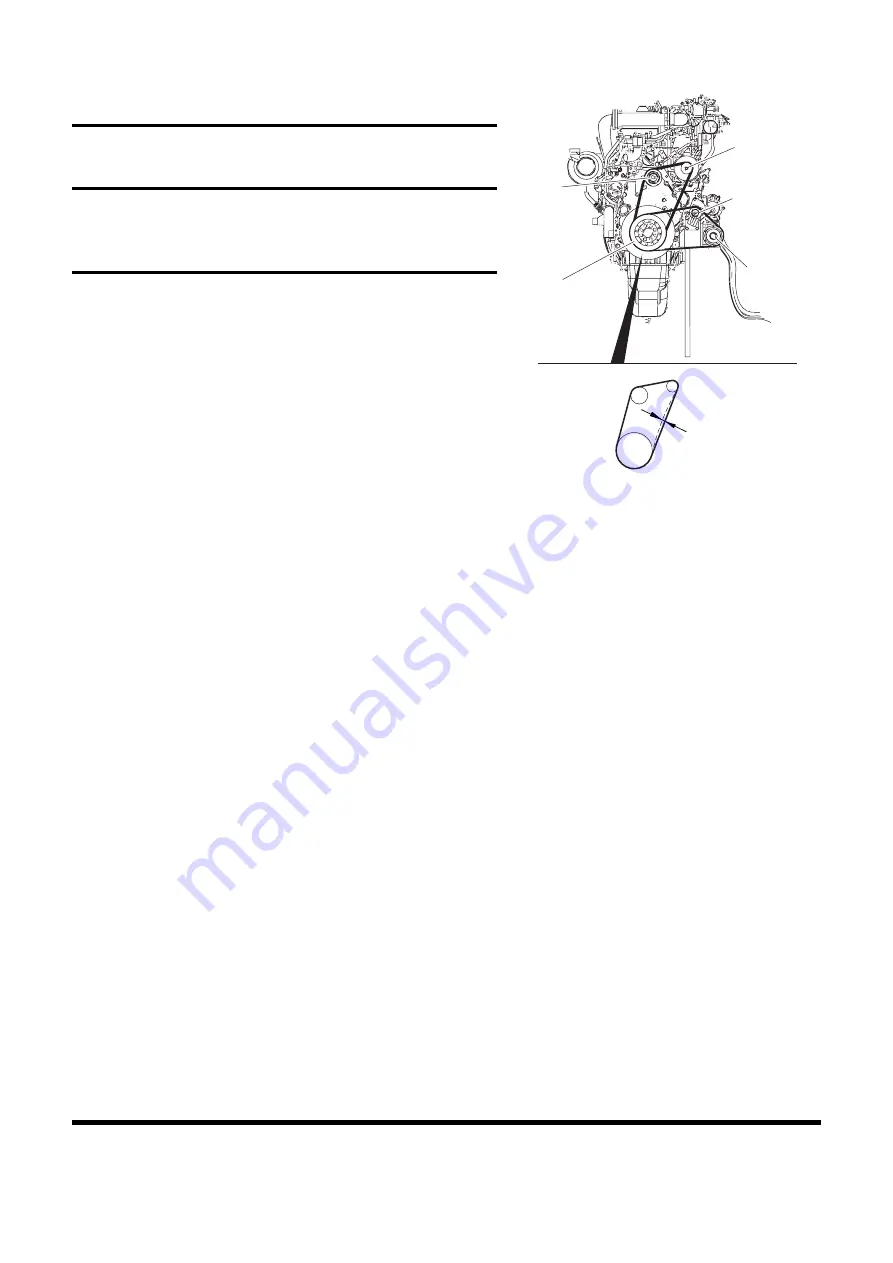

Check Engine Fan Belt Tension

1.

Inspect every 250 hours. (Inspect after first 50 hours of

operation.)

2.

With the engine shut off, check the tension of the fan belt

by pressing downwards on the belt, midway between the

fan pulley and alternator pulley. The belt should flex

approximately 6 - 8 mm (0.24 - 0.31 in). See Figure 44. To

adjust the belt, loosen the alternator adjustment plate bolts,

adjust the belt tension and retighten the bolts.

Alternator

Alternator

Idle Pulley

Compressor

Water

Pump

Water

Pump

6 - 8 mm (0.24 - 0.31 in)/

10 kg (22 Ib)

CRS

Pulley

CRS

Pulley

FG016161

Figure 44

IMPORTANT

A loose fan belt can cause engine overheating, poor

charging, and/or premature belt wear. A belt that is too tight

can cause damage to the water pump, alternator bearing or

belt.

Summary of Contents for DX700LC

Page 2: ......

Page 72: ...OP001120 Safety 1 66 ...

Page 142: ...OP001121 Operating Controls 2 70 ...

Page 188: ...OP001122 Operation 3 46 ...

Page 197: ...OP001123 4 9 Inspection Maintenance and Adjustment ...

Page 282: ...OP001123 Inspection Maintenance and Adjustment 4 94 ...

Page 298: ...OP000030 Troubleshooting 6 6 ...

Page 301: ...OP001125 7 3 Specification ...

Page 308: ...OP001125 Specification 7 10 ...

Page 314: ...950106 00012E Index 8 6 ...