4-73

Inspection, Maintenance and Adjustment

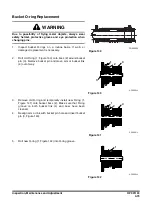

Bucket O-ring Replacement

1.

Inspect bucket O-rings on a routine basis. If worn or

damaged, replacement is necessary.

2.

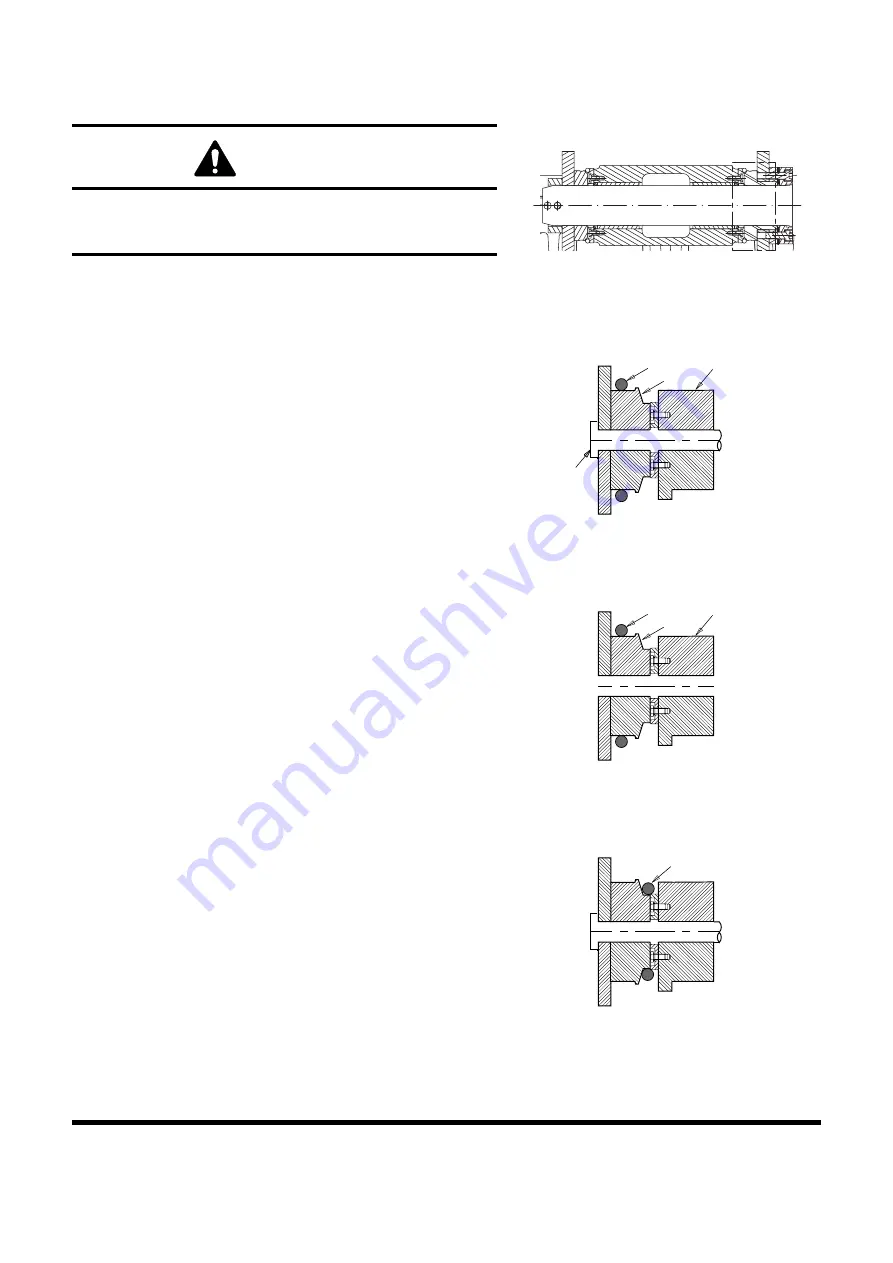

Roll old O-ring (1, Figure 140) onto boss (2) around bucket

pin (3). Remove bucket pin and move arm or bucket link

(4) out of way.

3.

Remove old O-ring and temporarily install new O-ring (1,

Figure 141) onto bucket boss (2). Make sure that O-ring

groove on both bucket link (4) and boss have been

cleaned.

4.

Realign arm or link with bucket pin hole and insert bucket

pin (3, Figure 140).

5.

Roll new O-ring (1, Figure 142) into O-ring groove.

FG000502

Figure 139

WARNING

Due to possibility of flying metal objects, always wear

safety helmet, protective gloves and eye protection when

changing pins.

ARO1390L

1

2

4

3

Figure 140

ARO1391L

1

2

4

Figure 141

ARO1392L

1

Figure 142

Summary of Contents for DX700LC

Page 2: ......

Page 72: ...OP001120 Safety 1 66 ...

Page 142: ...OP001121 Operating Controls 2 70 ...

Page 188: ...OP001122 Operation 3 46 ...

Page 197: ...OP001123 4 9 Inspection Maintenance and Adjustment ...

Page 282: ...OP001123 Inspection Maintenance and Adjustment 4 94 ...

Page 298: ...OP000030 Troubleshooting 6 6 ...

Page 301: ...OP001125 7 3 Specification ...

Page 308: ...OP001125 Specification 7 10 ...

Page 314: ...950106 00012E Index 8 6 ...