G80XW/XF, G115XW/XF, G150XW/XF, G200XW/XF - 50HZ

OPERATION & MAINTENANCE MANUAL

120

G100XW/XF, G135 XW/XF, G170XW/XF, G225XW/XF - 60Hz

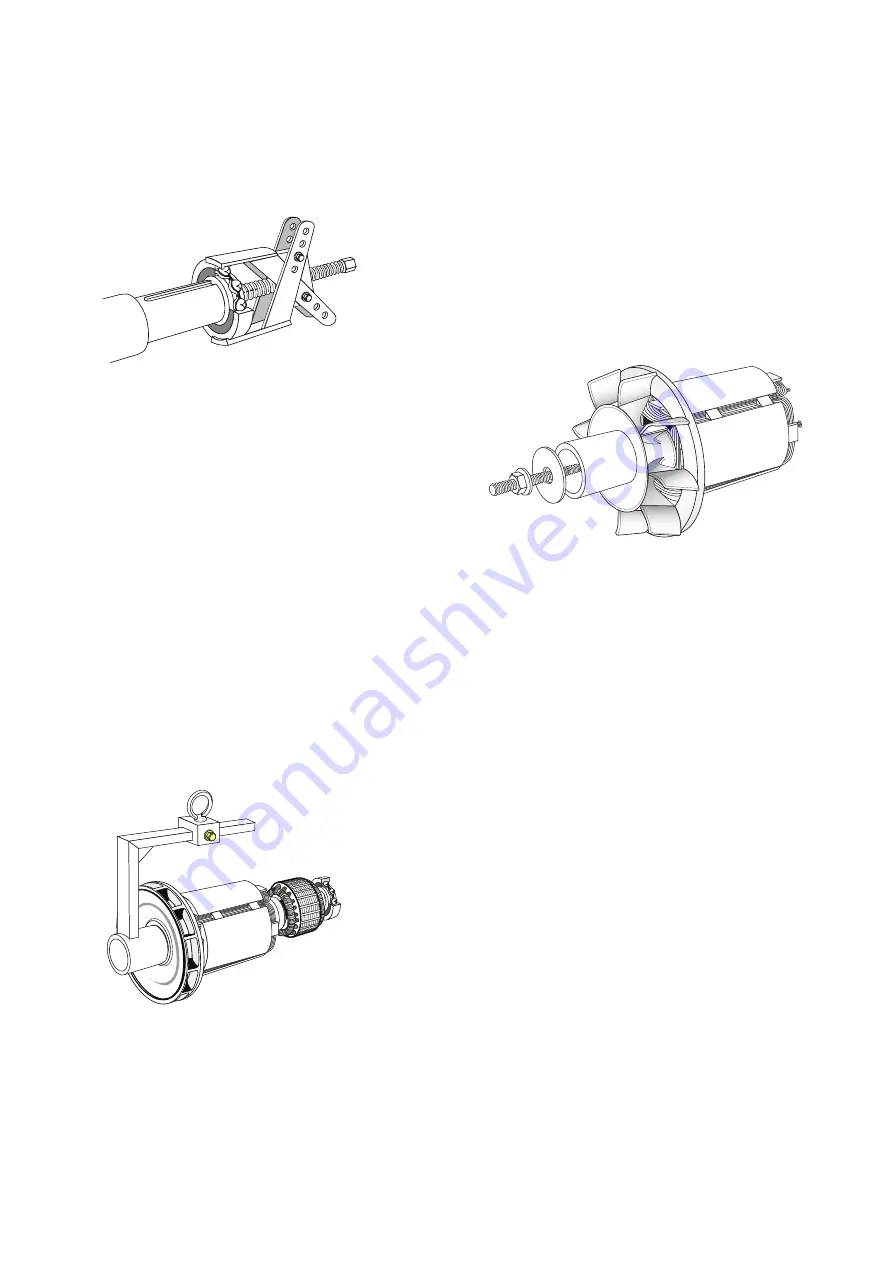

Replacing the NDE bearing on single-bearing

machines

Dismantling

•

Remove the NDE shield [36].

•

Remove the ball bearing [70] using a screw puller.

Reassembly

•

Heat the inner slip ring of a new bearing by induction

or in a drying oven at 80 °C (do not use an oil bath)

and fit it to the alternator.

•

Place the preloading wavy washer [79] in the flange

and fit a new O ring seal [349].

•

Replace the NDE bracket [36].

Accessing the main field and stator

Dismantling

Follow the procedure for dismantling bearings.

•

Remove the coupling discs (single-bearing alternator)

or the DE flange (two-bearing alternator) and insert a

tube of the corresponding diameter on the shaft end

or a support made according the following bellow.

•

Rest the rotor on one of its poles, then slide it out. Use

the tube as a lever arm to assist dismantling.

•

After extraction, be careful with the fan. It is necessary

to replace the fan in case of disassembling.

•

After extracting the rotor, be careful not to damage the

fan and place the revolving field on special V-blocks.

NOTE: If intervention is required on the main field

(rewinding, replacement of components), the

rotor assembly must be rebalanced.

Reassembly

•

Follow the dismantling procedure in reverse order.

Take care not to knock the windings when refitting the

rotor in the stator.

If you replace the fan, respect the assembly guide

according the following bellow. Use a tube and a screw.

Follow the procedure for reassembling the bearings.