G80XW/XF, G115XW/XF, G150XW/XF, G200XW/XF - 50HZ

OPERATION & MAINTENANCE MANUAL

92

G100XW/XF, G135 XW/XF, G170XW/XF, G225XW/XF - 60Hz

CYLINDER COMPRESSION PRESSURE

1. Start and warm up the engine.

2. Stop the engine and disassemble the fuel injection

nozzle holder assembly.

3. Install a special tool, compression pressure gauge

adapter in the fuel injection nozzle holder hole.

4. Connect the compression pressure gauge to the

adapter.

NOTE:

Testing conditions: at water temperature of 20°C

and speed of 200 rpm (10 turns)

ELECTRICAL SYSTEM

BATTERY

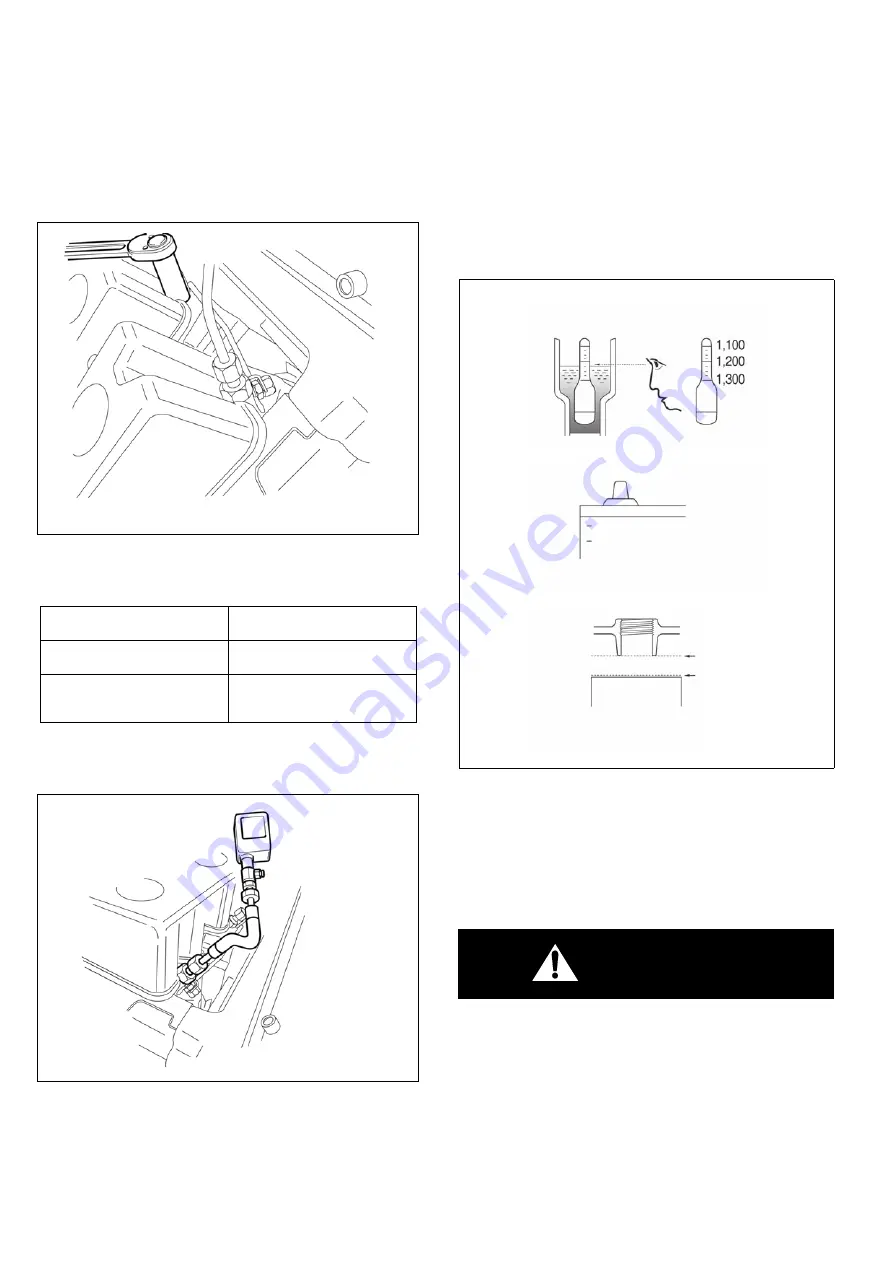

•

Check the battery for cracks and ensure there is no

electrolyte leakage. Replace the battery if defective.

•

Check the amount of electrolyte, and replenish

distilled water if insufficient.

•

Check the specific gravity of electrolyte. If it is below

the specified value (1.12 ~ 1.28), replenish it.

STARTER

When servicing the engine, immerse the starter motor’s

pinion gear and ring gear in the fuel, wash them

completely, and apply grease again. When cleaning the

surrounding of engine, ensure that no water enters the

starter.

CAUTION

Starter should be protected from humidity at all

times.

Before working on the electric system, be sure to

disconnect the ground wire (“-” minus wire) of the

battery. Short circuit may occur while working on the

electrical system. Reconnect the ground wire last

after completing all of work.

Standard

Above 28kg/cm

2

Tolerance limit

24kg/cm

2

Difference between each

cylinder

Within ±10%

DV2213046A

EA9O5004

Viewing the

gravity meter

Liquid level

indicating line

liquid level upper limit

liquid level lower limit

UPPER LEVEL

LOWER LEVEL

lsotator