Maintenance

- 79 -

3.3. Engine Reassembly

3.3.1. General precautions

Clean all the disassembled parts, particularly oil and water ports, using compressed air, then check

that they are free from restrictions.

Arrange the general and special tools in order for engine assembly operation.

To wet each sliding part, prepare the clean engine oil.

Prepare service materials such as sealant, gaskets, etc.

Discard used gaskets, seal rings, and consumable parts, and replace with new ones.

Apply only the specified torque for bolts in the specified tightening order and avoid over-tightening.

Be sure to check that all the engine parts operate smoothly after being reassembled.

Check the bolts for looseness after reassembly.

After completing the engine reassembly operation, check if there is missing parts or shortage of parts.

Keep your hands clean during the working.

3.3.2. Cylinder block

Cover the floor of the workshop with wood plate or thick paper to prevent damage to the cylinder

head and place the cylinder block with the head fitting surface facing downward.

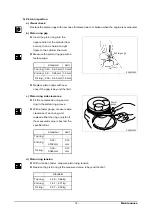

3.3.3. Cylinder liner

Stand the cylinder block so that the

flywheel faces downward.

Thoroughly clean the liner flange fitting

surface and bore inside with compressed

air to prevent the entry of foreign

substances.

After the cleaning operation, make the

cylinder liner dried up and push it into the

cylinder block by hand.

Wet the liner inside diameter with engine

oil.

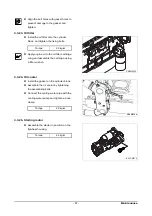

3.3.4. Oil spray nozzle

Tighten and assemble the oil spray

nozzle flange with fixing bolts using the

spray nozzle jig.

EAMD087I

EDM3053I

Torque

4.5 kg

•

m

Summary of Contents for GL08K

Page 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Page 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Page 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Page 195: ...Special Tool List 950106 080002 ...

Page 196: ......