Troubleshooting

Operation & Maintenance Manual

83

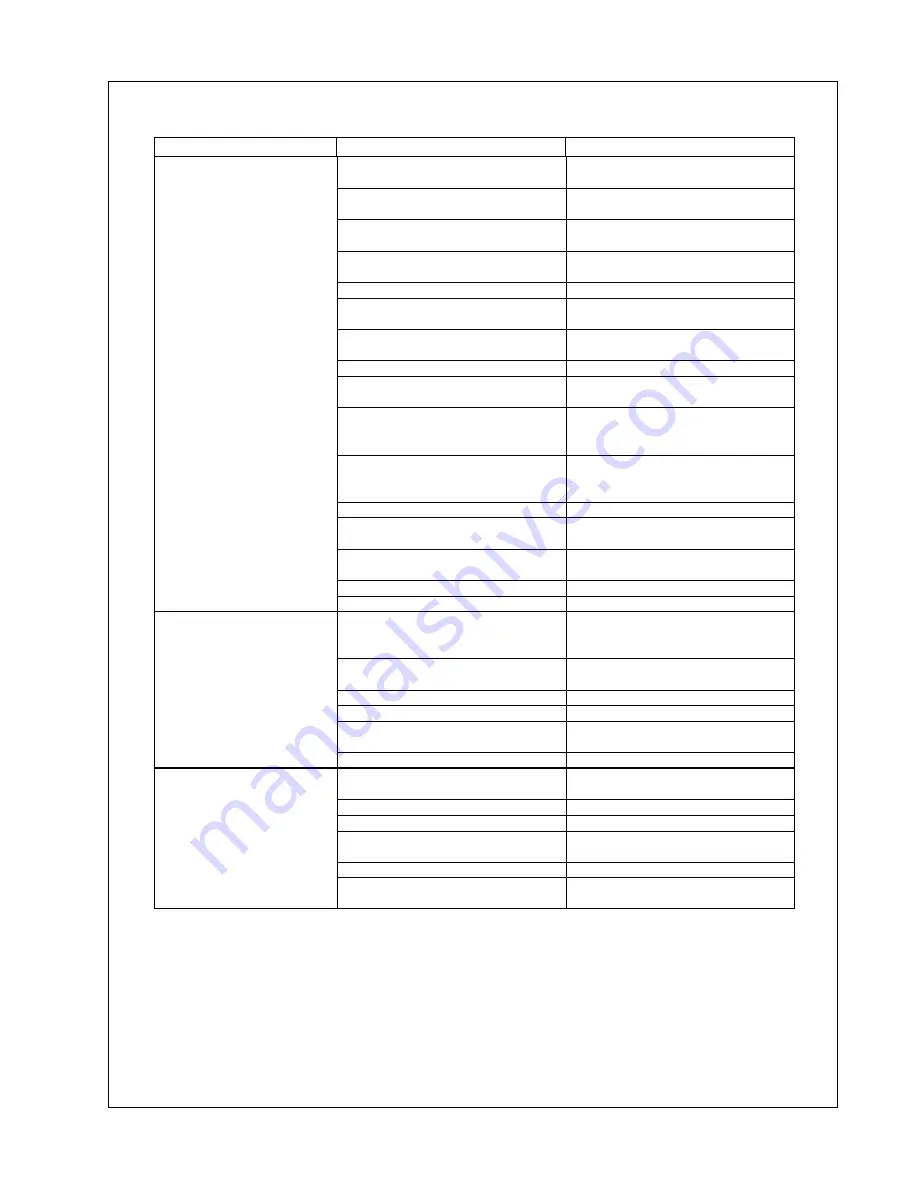

Complaint

Cause

Correction

6. High compressor oil

temperature

Ambient temperature above rated

ambient temperature range.

Operate in cooler environment.

Compressor tilted beyond out-of-level

operating limit.

Reposition or relocate compressor to

be more level.

Low compressor oil level.

Add compressor oil. Look for and

repair any leaks.

Wrong compressor oil.

Change compressor oil. Review

compressor oil specification.

Dirty cooler(s).

Clean exterior of cooler(s).

Dirty operating conditions.

Move compressor to cleaner

environment.

Clogged compressor oil filter(s).

Replace compressor oil filter(s) and

change compressor oil.

Loose or broken belts.

Tighten or replace belt set.

Operating pressure too high.

Reduce pressure to rated operating

pressure.

Recirculation of cooling air.

Close enclosure doors. Close and

secure access panels. Check for loose

or missing belly pans.

Malfunctioning compressor oil

thermostat.

Replace thermostat element in

conventional bypass valve, if equipped.

Loose or broken belts.

Tighten or replace belt set.

Replace valve.

Malfunctioning minimum pressure

valve.

Repair or replace valve.

Blocked or restricted oil lines.

Clean by flushing, or replace lines.

Airend malfunctioning.

See Complaints #11, #12.

g

p

,

7. Low engine speed

Clogged fuel filters.

Service fuel filters. See Engine

manual. Drain and clean fuel tanks.

Add clean fuel.

Operating pressure too high.

Reduce pressure to rated operating

pressure.

Clogged air filter element(s).

Clean or replace air filter element(s).

Wrong air filter element(s).

Install correct air filter element(s).

Engine malfunctioning.

See troubleshooting in Engine manual.

Airend malfunctioning.

See Complaints #11, #12.

8. Excessive vibration

Rubber mounting isolators loose or

damaged.

Tighten or replace.

Defective or imbalanced fan.

Replace fan.

Defective airend drive coupling.

Replace coupling.

Engine malfunctioning.

See troubleshooting in Engine manual.

Airend malfunctioning.

See Complaints #7, #11, #12.

Engine idle speed too low.

See Complaint #7. See Engine

manual.

Summary of Contents for HP450/VHP400WCU-T4i

Page 2: ...2 ...

Page 6: ...6 ...

Page 7: ...7 Foreword ...

Page 10: ...Operation Maintenance Manual Foreword 10 ...

Page 11: ...11 Safety ...

Page 21: ...Safety Operation Maintenance Manual 21 ...

Page 22: ...Operation Maintenance Manual Safety 22 ...

Page 23: ...Safety Operation Maintenance Manual 23 ...

Page 28: ...Operation Maintenance Manual Safety 28 ...

Page 29: ...29 Noise Emission ...

Page 35: ...35 General Data ...

Page 38: ...Operating Maintenance Manual General Data 38 ...

Page 39: ...39 Operating Instructions ...

Page 56: ...Operating Maintenance Manual Operating Instructions 56 ...

Page 57: ...57 Maintenance ...

Page 74: ...Operation Maintenance Manual Maintenance 74 ...

Page 75: ...75 Lubrication ...

Page 79: ...79 Troubleshooting ...

Page 99: ...Troubleshooting Operation Maintenance Manual 99 ...

Page 100: ...Operation Maintenance Manual Troubleshooting 100 ...

Page 101: ...103 Options ...

Page 107: ...Revision History Rev EC Number Comments A CN023581 Original release ...