Operation & Maintenance Manual

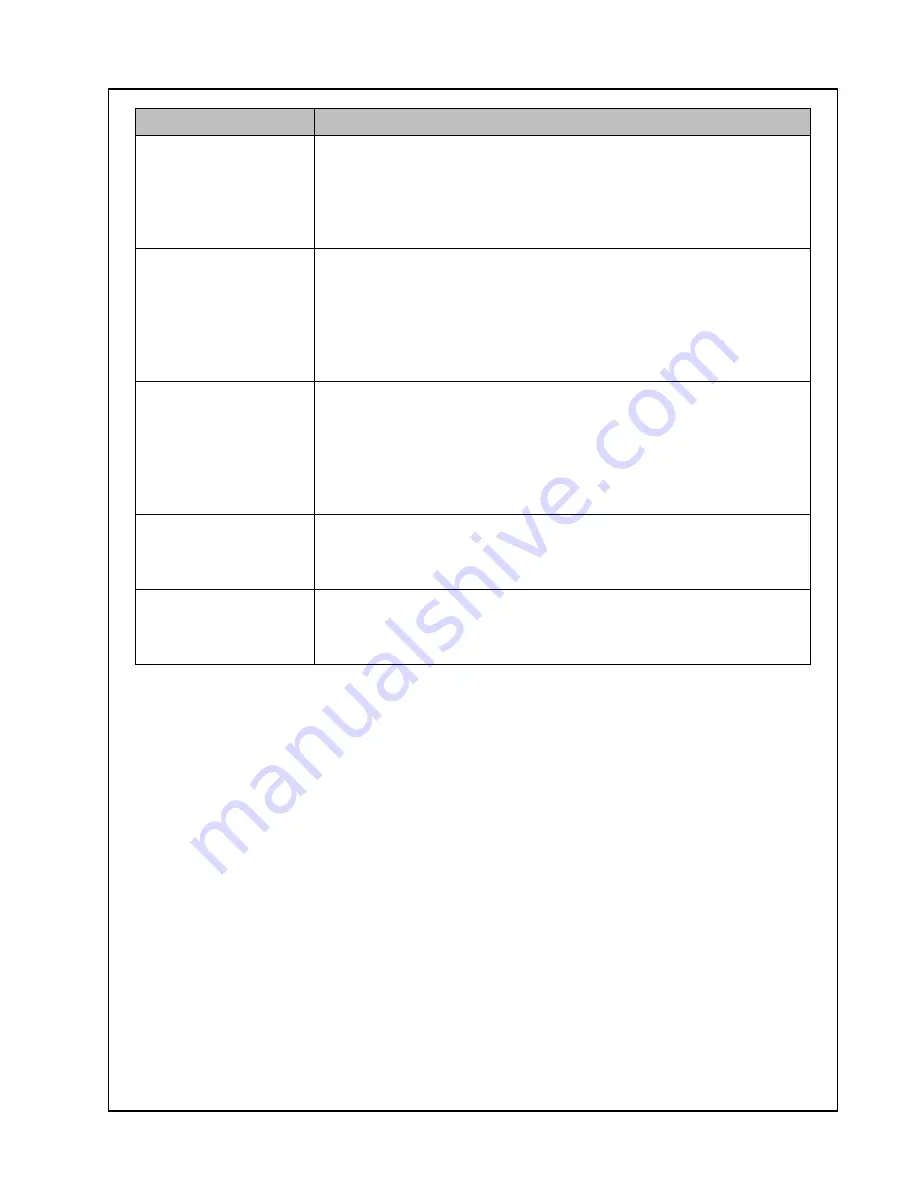

PERIOD

DESCRIPTION

100 HOURS

AIR INTAKE AND ENGINE EXHAUST

Engine and compressor air intake and engine exhaust systems

should be inspected after each 100 hours of operation for loose,

damaged, or deteriorated components. Repairs or replacements

should be made before the next period of use.

250 HOURS

COOLING SYSTEMS

All components of the cooling system for engine water and

compressor oil should be inspected every 250 hours of use.

Any discrepancies found should be corrected before placing the

compressor back in operation. Unrestricted airflow over the radiator

and oil cooler must be maintained at all times during operation.

250 HOURS

ISOLATION MOUNTS

Engine/Airend isolation mounts should be inspected after each

250 hours of operation. Those mounts with cracks or splits in the

molded rubber or with bent or broken bolts due to operation or

storage in severe environments should be replaced with equivalent

parts.

See Operator Manual

ENGINE OPERATION

Inspect and maintain engine condition and operation as

recommended in the manuals supplied by the engine manufacturer.

See Operator Manual

FUELS AND LUBRICANTS

Use only the types and grades of fuels and lubricants recommended

in the Operator and Maintenance Manual and Engine Manual.

31

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......