Operation & Maintenance Manual

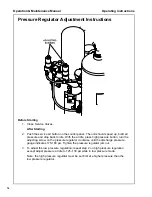

185 cfm at 150 psi regulated set pressure. The regulated set pressure of this mode

can be changed (see Pressure Regulating Adjusting Instructions) from 80-150 psi.

The mode of the compressor can be changed between the Low and High at anytime. Engine

speed will be lower at the HI Pressure Mode setting.

Operation Loaded

Assume engine has been started and is running in the unload state at idle speed. If there is air

demand (pressure falls below the load point pressure), compressor will load at idle speed by

opening the inlet valve. As air demand rises and falls, engine speed is controlled between idle

speed and full load speed to match the required flow while maintaining load point pressure.

Operation Unloaded

If there is no air demand at idle speed (pressure rises above the unload point pressure), the

compressor will unload by closing the inlet valve. The compressor then runs at idle speed

unloaded with no air delivery. If air demand increases (pressure falls below the load point

pressure), the compressor reloads to meet the required air demand.

Shutdown

1. Close all service valves.

2. Allow the engine to idle for 3 minutes to cool down.

3. Press the red stop button.

4. Press the main power button when use of the compressor is not needed.

Note:

until main power button is pressed, the gauges can be read and the mini-port

can be navigated using the UP, DOWN, and ENTER Buttons.

5. If the Main Power Button is not pressed within 3 minutes (if ambient temperature is

above 45° F (7° C) or 15 minutes if ambient temperature is 45° F (7° C) or below of

the keypad use the compressor will automatically shut off.

Since the service valve is closed, air downstream of the valve may be

trapped. A vent hole in the service valve will slowly bleed air from the

hose. Do not disconnect hoses until all pressure has been vented.

Do NOT wire around or bypass a shutdown sensor or switch.

53

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......