Operation & Maintenance Manual

4. Pull out safety element if installed.

5. Install new filters in air cleaner body.

6. Re-install cover on air cleaner body.

7. Close the 2 latches after securing to air cleaner body.

Make sure that all clamps and flange joints are tight. Make sure the pre-cleaner dirt dump is

pointed within 30° of down.

Gauges

The instruments or gauges are essential for safety, maximum productivity and long service

life of the machine. Inspect the gauges and test any diagnostic lamps prior to start-up. During

operation observe the gauges and any lamps for proper functioning. Refer to Operating

Controls, for the normal readings.

Fuel Tank

CLEAN fuel in the fuel tanks is vitally important and every precaution should be taken to

ensure that only clean fuel is poured or pumped into the tank.

When filling the fuel tank on this unit, by methods other than a pump and hose, use a CLEAN

non-metallic funnel.

Battery

Keep the battery posts-to-cable connections clean, tight and lightly coated with a grease.

Also the electrolyte level in each cell should cover the top of the plates. If necessary, top-up

with clean distilled water.

Tires

A weekly inspection is recommended. Tires that have cuts or cracks or little tread should be

repaired or replaced. Monthly check the wheel lug nuts for tightness.

Fasteners

Visually check entire unit in regard to bolts, nuts and screws being properly secured. Spot

check several capscrews and nuts for proper torque. If any are found loose, a more thorough

inspection must be made. Take corrective action.

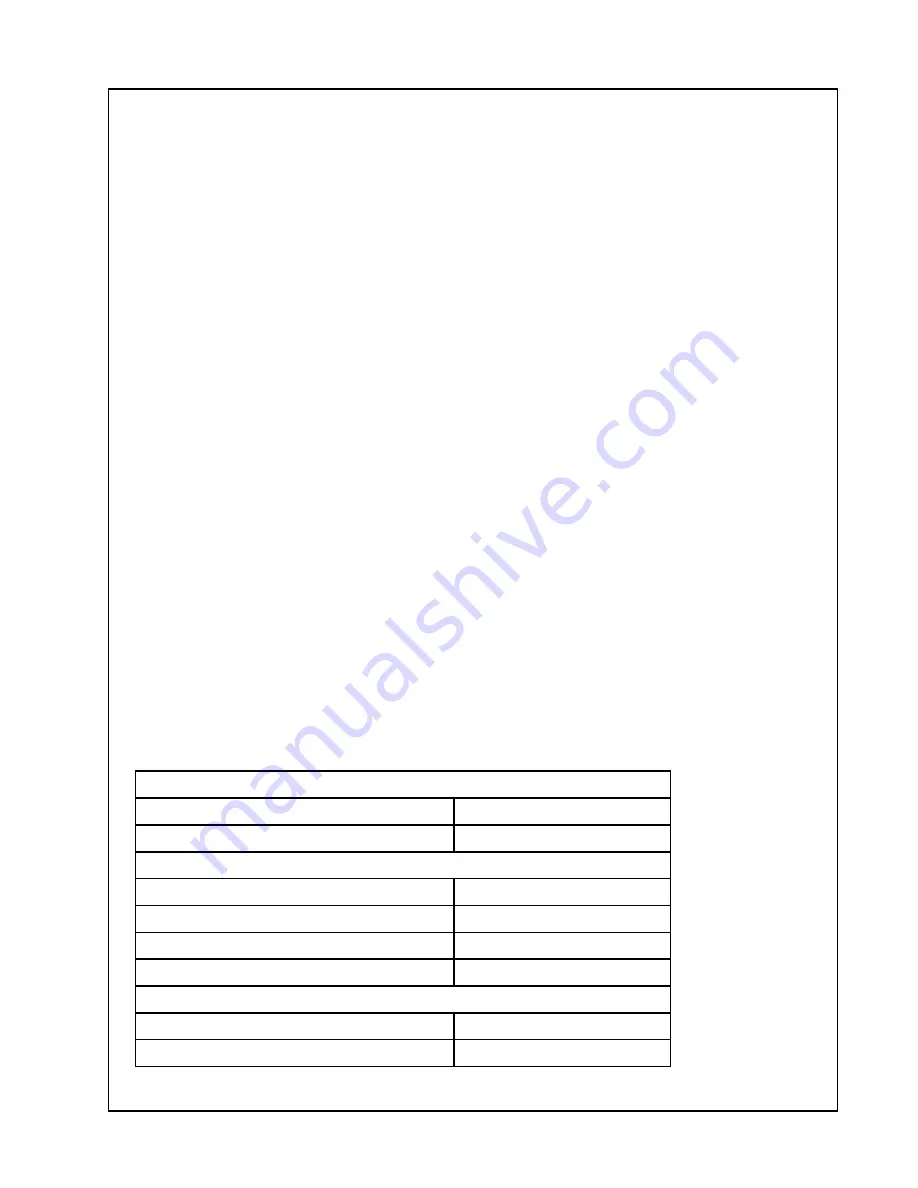

Wheel Torque Chart

M12 Bolts

Torque (Ft-Lbs)

13” Wheel

60-70

1/2” Lug Nuts

13” Wheel

80-90

15” Wheel

105-115

16” Wheel

105-115

16.5” Wheel

105-115

5/8” Lug Nuts

16” Wheel

190-210

17.5” Wheel

190-210

93

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......