Operation & Maintenance Manual

This should remove the accumulation of grease, oil and dirt from the exterior surfaces of the

oil cooler core so that the entire cooling area can transmit the heat of the lubricating and

cooling oil to air stream.

In the event foreign deposits, such as sludge and lacquer, accumulate in the oil cooler to

the extent that its cooling efficiency is impaired, a resulting high discharge air temperature is

likely to occur, causing shut down of the unit. To correct this situation it will be necessary to

clean it using a cleaning compound in accordance with the manufacturer’s recommendations.

Compressor Oil

The lubricating and cooling oil must be replaced every 500 hours of operation or six (6)

months, whichever comes first. Refer to warranty section about extended warranty.

Receiver Separator System

High pressure air can cause severe injury or death from hot oil and flying

parts. Always relieve pressure before removing caps, plugs, covers or

other parts from pressurized air system.

•

Open service valve at end of machine.

•

Ensure pressure is relieved, with BOTH:

•

— Discharge air pressure gauge reads zero (0).

— No air discharging from service valve.

Remove plug near bottom of separator tank to drain compressor oil.

When adding oil, remove and replace (make tight) plug on top of separator tank.

The life of the oil separator element is dependent upon the operating environment (soot,

dust, etc.) and should be replaced every twelve months or 1000 hours. To replace the

element proceed as follows:

•

Ensure the tank pressure is zero.

•

Unscrew separator element from manifold.

•

Lubricate gasket with compressor oil. Install new element.

96

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

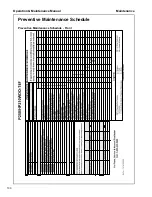

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......