Operation & Maintenance Manual

Scavenge Line

High Pressure Air can cause severe injury or death from hot oil and

flying parts. Always relieve pressure before removing caps, plugs,

covers or other parts from pressurized air system.

The scavenge line originates at the manifold and terminates at the compressor airend near

the oil filter element. An orifice check valve is located on the scavenge tube.

Once a year or every 1000 hours of operation, whichever comes first, replace the separator

element and clean the scavenge orifice/check valve.

NOTE: Excessive oil carry-over may be caused by an oil-logged separator element. Do not

replace element without first performing the following maintenance procedure:

1. Check oil level. Maintain as indicated earlier in this section.

2. Thoroughly clean scavenge line, any orifice and check valve.

3. Assure minimum pressure valve/orifice is operational.

4. Run unit at rated operating pressure for 30 to 40 minutes to permit element to clear

itself.

Exterior Finish Care

This unit was painted and heat cured at the factory with a high quality, thermoset polyester

powder coating. The following care will ensure the longest possible life from this finish.

1. If necessary to remove dust, pollen, etc. from housing, wash with water and soap or

dish washing liquid detergent. Do not scrub with a rough cloth, pad, etc.

2. If grease removal is needed, a fast evaporating alcohol or chlorinated solvent can be

used. Note: This may cause some dulling of the paint finish.

3. If the paint has faded or chalked, the use of a commercial grade, nonabrasive

automotive car wax may partially restore the color and gloss.

Field Repair of Texture Paint

1. The sheet metal should be washed and clean of foreign material and then thoroughly

dried.

2. Clean and remove all grease and wax from the area to be painted using Dupont

3900S Cleaner prior to sanding.

3. Use 320 grit sanding paper to repair any scratches or defects necessary.

4. Scuff sand the entire area to be painted with a red Scotch Brite™ pad.

5. Wipe the area clean using Dupont 3900S.

97

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

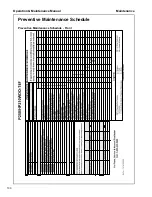

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......