Operation & Maintenance Manual

Regular Inspection

General Information

Engine oil lubricates, cools, seals, prevents corrosion, and cleans engines, enhancing engine

performance and extending the engine's lifetime. If the engine is continuously operated while

engine oil is insufficient the moving parts of the engine may get stuck, causing engine faults.

Engine oil should be checked with the oil level gauge and replenished if required. Oil level

should be checked while the engine is shut down. To check the oil level, shut down the engine

and wait for 5 ~10 minutes to allow the engine oil to flow back into the oil pan. The engine oil

level should indicate between the upper limit and the lower limit of the oil level gauge.

Engine oil should be periodically replaced based on the regular inspection table and the oil

filter and the cartridge should be replaced as the engine oil is replaced.

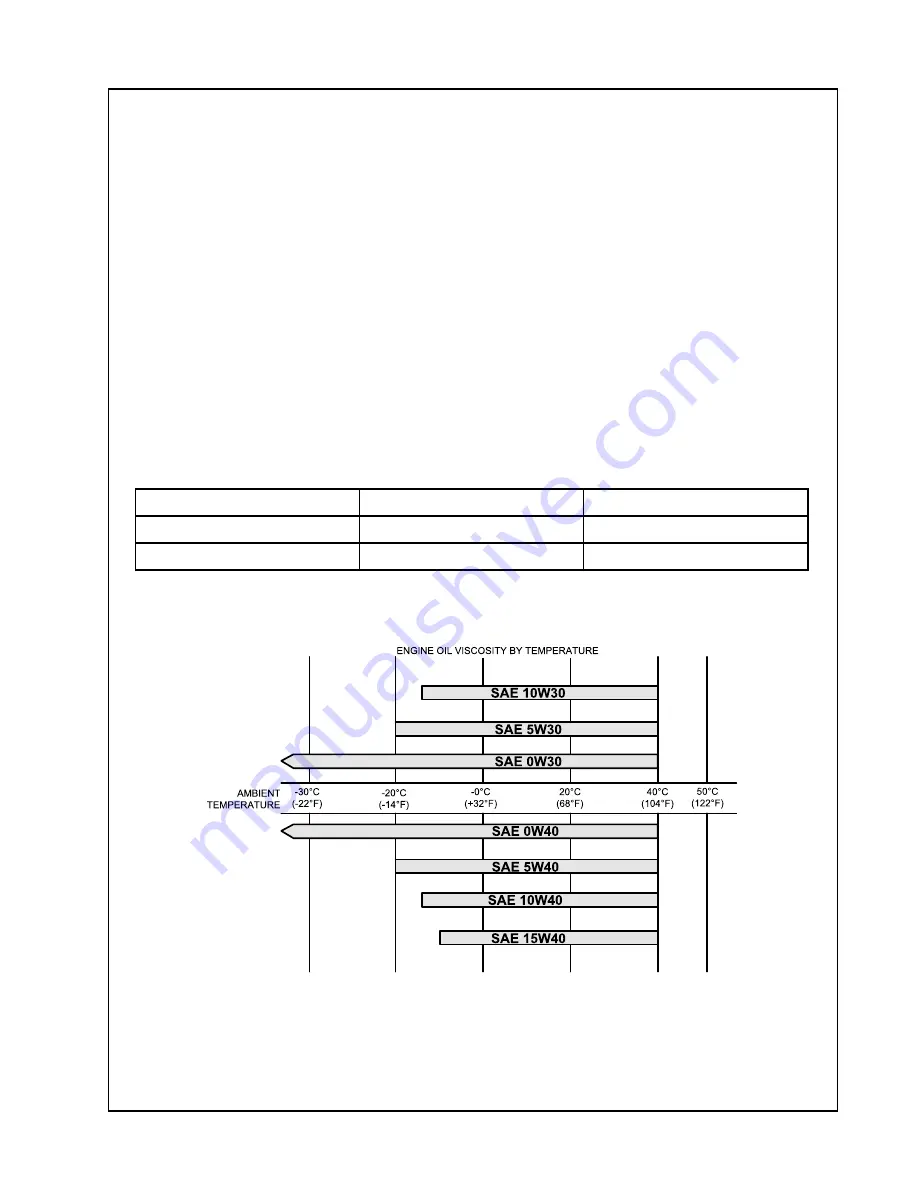

Engine Oil Standards

Use the specified engine oil suitable for the environment and conditions of the site where

the engine will be used.

Please use the engine oil which satisfies the following recommended specifications.

Engine Model

SAE Classification

Oil Class

DL01/DL02

SAE 10W30

API CJ-4 or Better

DL01/DL02

SAE 15W40

API CJ-4 or Better

Note: Doosan engine oils are recommended for use in this machine. If Doosan engine oil

is not available, use a good quality engine oil that meets API service classification of CJ-4

or Better.

69

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......