Operation & Maintenance Manual

General Information

Any unauthorized modification or failure to maintain this equipment may

make it unsafe and out of factory warranty.

If performing more than visual inspections, disconnect battery cables

and open manual blowdown valve.

Use extreme care to avoid contacting hot surfaces (engine exhaust

manifold, piping, air receiver, and air discharge piping, etc.).

Never operate this machine with any guards removed.

Inch and metric hardware was used in the design and assembly of this

unit. Consult the parts manual for clarification of usage.

Disregard any maintenance pertaining to components not provided on

your machine.

In addition to periodic inspections, many of the components in these units require

periodic servicing to provide maximum output and performance. Servicing may consist

of pre-operation and post-operation procedures to be performed by the operating or

maintenance personnel. The primary function of preventive maintenance is to prevent failure,

and consequently, the need for repair. Preventive maintenance is the easiest and the least

expensive type of maintenance. Maintaining your unit and keeping it clean at all times will

facilitate servicing.

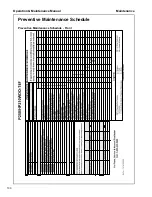

Scheduled Maintenance

The maintenance schedule is based on normal operation of the unit. This page can

be reproduced and used as a checklist by the service personnel. In the event unusual

environmental operating conditions exist, the schedule should be adjusted accordingly.

Compressor Oil Level

Check the compressor fluid level when the machine is not operating. Maintain the fluid level

between bottom and midway of the sight glass on the separator tank.

Air Cleaner

To service the air cleaners on all units proceed as follows:

1. Loosen the 2 latches on the sides of the air cleaner cover.

2. Remove air cleaner body.

3. Pull out air cleaner element.

92

Summary of Contents for Infracore HP210WDO-T4F

Page 2: ......

Page 3: ...iii...

Page 4: ......

Page 8: ...8...

Page 9: ...Foreword 9...

Page 12: ...12...

Page 13: ...Drawbar Instructions 13...

Page 16: ...16...

Page 17: ...Safety 17...

Page 25: ...Safety Operation Maintenance Manual 25...

Page 26: ...26...

Page 27: ...Noise Emission 27...

Page 32: ...32...

Page 33: ...General Data 33...

Page 36: ...36...

Page 37: ...Operating Instructions 37...

Page 55: ...Engine Operation 55...

Page 86: ...86...

Page 87: ...Lubrication 87...

Page 90: ...90...

Page 91: ...Maintenance 91...

Page 99: ...99...

Page 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Page 102: ...102...

Page 103: ...Troubleshooting 103...

Page 114: ...114...

Page 115: ...Appendix A 115...

Page 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Page 117: ...Appendix A Operation Maintenance Manual 117...

Page 118: ...Operation Maintenance Manual Appendix A 118...

Page 120: ......

Page 121: ......