64

PERIODICAL INSPECTION AND MAINTENANCE

.

7/20, P65

Inspection every 50 hours operation

(1) Inspection of battery

Fire due to electric short

−

circuit

Make sure to turn off the battery switch or

disconnect the negative cable

(

−

)

before

inspecting the electrical system. Failure to do so

could cause short

−

circuiting and fires.

Always disconnect the

(

−

)

Negative battery

cable first before disconnecting the battery cables

from battery. An accidental “Short circuit” may

cause damage, fire and or personnel injury.

And remember to connect the (

−

)

Negative battery cable (back onto the

battery) LAST.

Proper ventilation of the battery area

Keep the area around the battery Well ventilated,

paying attention to keep away any fire source.

During operation or charging, hydrogen gas is

generated from the battery and can be easily

ignited.

Do not come in contact with battery electrolyte

Pay sufficient attention to avoid your eyes. or skin

from being in contact with the fluid. The battery

electrolyte is dilute sulfuric acid and causes burns.

Wash it off immediately with a large amount of

fresh water if you get any on you.

Clean the battery terminals

Check the level of fluid in the battery.

When the amount of fluid nears the lower limit, fill with battery fluid

(available in the market) to the upper limit. If operation continues with

insufficient battery fluid, the battery life is shortened, and the battery

may overheat and explode.

Battery fluid tends to evaporate more quickly in the summer, and the

fluid level should be checked earlier than the specified limes.

If the

engine cranking speed is so slow that the engine

does not start

up, recharge the battery.

If the engine still will not start after charging, replace the battery.

Remove the

battery from the battery mounting of the machine unit

after daily use if letting the machine unit leave in the place that the

ambient temperature could drop at

−

15

C or less. And store the battery

in a warm place until the next use the unit to start the engine easily at

low ambient temperature.

OPTION

Follow the instructions an precautions in the manual from the battery

maker.

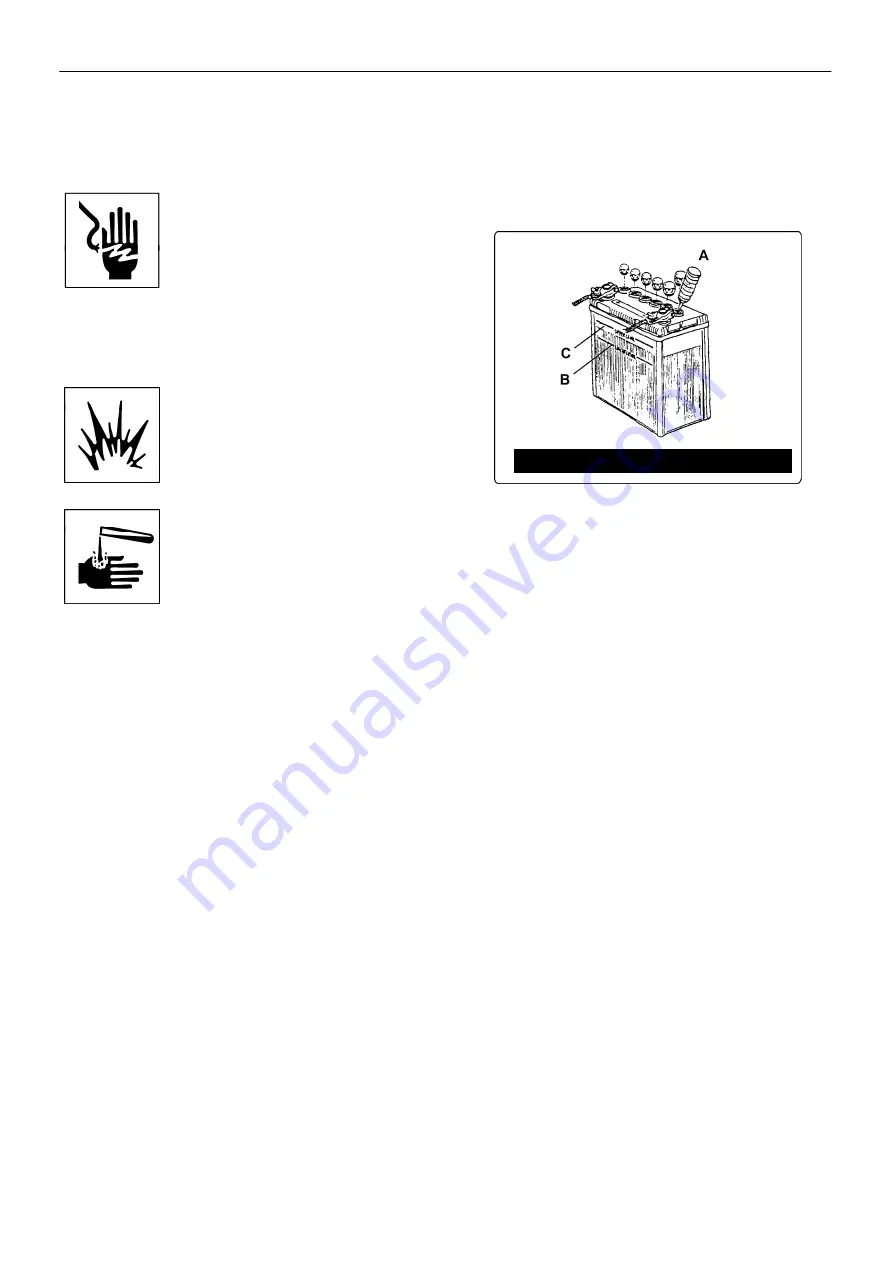

A.

Battery fluid

B.

Lower limit

C.

Upper limit

Inspection every 200 hours operation

(1) Draining and cleaning of the fuel tank

1) Prepare a waste oil container.

2) Take off the fuel tank.

3) Remove the cap of the fuel tank to drain (water, dust ,etc.) from the

fuel tank bottom.

4) Drain fuel and clean fuel tank.

5) Put back the fuel tank.

(2) Cleaning The Fuel Filter Pot.

Clean the fuel filter in a clean place to prevent dust intrusion.

1) Close the fuel filter lever.

2) Remove the top cap, and rinse the inside with diesel fuel.

3) Take out the element, and rinse it with diesel fuel.

4) After cleaning, reinstall the fuel filter, keeping out of dust and dirt.

5) Air

−

bleed the injection pump.