OPTIONS

48

7/20, P65

LUBRICATOR

SAFETY

WARNING: Ensure that the lubricator filler cap is re

−

tightened

correctly after replenishing with oil.

WARNING: Do not replenish the lubricator oil, or service the

lubricator without first making sure that the machine is stopped

and the system has been completely relieved of all air pressure

(Refer to

STOPPING THE UNIT

in the

OPERATING

INSTRUCTIONS

section of this manual).

CAUTION:

If the nylon tubes to the lubricator are disconnected then

ensure that each tube is re

−

connected in its original location.

GENERAL INFORMATION

Oil capacity:

2 litres

Oil specification:

Refer to the

Tool Manufacturer’s Manual

.

OPERATING INSTRUCTIONS

COMMISSIONING

Check the lubricator oil level and fill as necessary.

PRIOR TO STARTING

Check the lubricator oil level and replenish as necessary.

MAINTENANCE

Check the lubricator oil level and replenish as necessary.

FAULT FINDING

FAULT

CAUSE

REMEDY

No oil flow.

Incorrect

connection.

Reverse the nylon tube

connections to the lubricator.

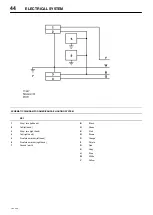

BUNDED BASE

Description

This machine can be fitted with bund equipment to contain leakages

and spillages, which occur within the machine enclosure.

The bund will contain all fluids normally installed in the machine, plus

an additional 10%.

When fitted with bund, the machine must only be operated within

$

3

degrees of level.

Drains for engine water & oil and compressor oil are located at the front

corner of the machine

The rear air intake is covered to prevent rainwater ingress. Ensure that

the cover is not prevented from moving

Draining of contaminated fluids

Contaminated fluid must be removed by authorized personnel only.

Captured fluids can be drained from the bund by uncoupling the flexible

pipe secured at the rear / side. This pipe must be re

−

secured after

draining.

Drainage of machine fluids

During maintenance operations drain machine fluids using the drain

ports indicated

Remove fuel tank to drain.

WARNING: Major leakages or spillages must be drained before

the machine is towed.