60

ENGINE MAINTENANCE SCHEDULE

7/20, P65

When performing the following items, the daily inspection items should also be carried out.

IMPORTANT:

Establish a periodic check plan according to the operating conditions and make sure to conduct checks at specified intervals. Otherwise,

malfunctioning may occur to shorten the engine life.

As special knowledge and skill are required for items marked with

, consult your local Ingersoll Rand branch or distributor.

: Check

: Replace

: Contact your dealer

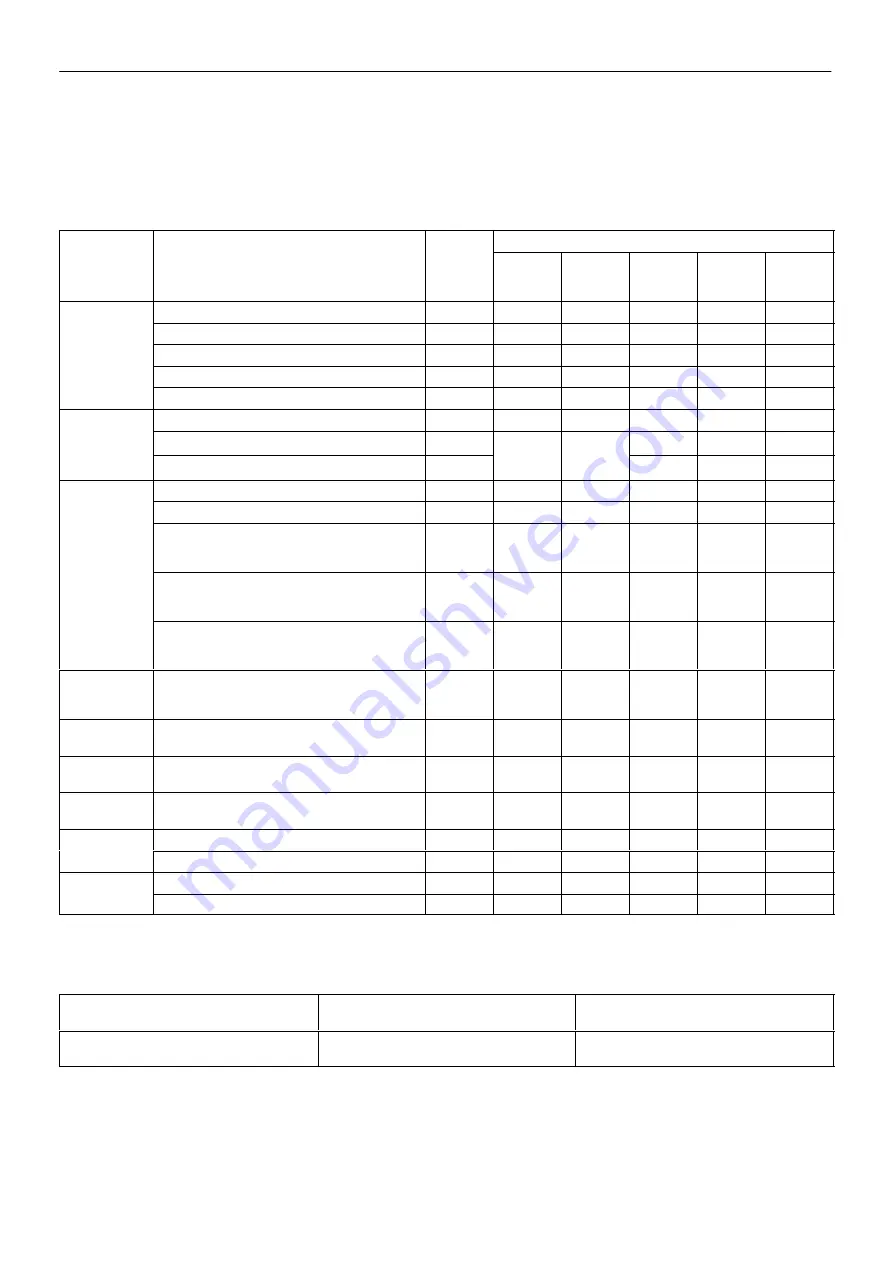

Periodic inspection interval

System

Check item

Daily

Every 50

hours

Every 200

hours

Every 400

hours

Every 800

hours

Every

2000

hours

Fuel

Fuel tank level check and refill

Cleaning fuel tank

Draining from fuel / water separator

Cleaning fuel / water separator

Fuel filter replacement

Engine oil level

Engine oil

Engine oil replacement

1st time

2nd &

g

Engine oil filter replacement

1st time

2nd &

after

Check & addition cooling

Radiator fin checking & cleaning

Cooling water

Cooling fan V

−

belt checking, adjusting &

replacement

1st time

2nd &

after

Cooling water

Cooling water replacement

or every 1

yr

Cooling water path flushing & maintenance

or every 2

yrs

Rubber hoses

Fuel & cooling water pipe replacement

or every 2

yrs

Operating

system

Governor lever & accelerator check & adjust

Intake and

exhaust

Air cleaner element cleaning & replacement

Electrical

equipment

Battery electrolyte check and recharging

Cylinder head

Adjust intake

I

exhaust valve clearance

Cylinder head

Lapping intake

I

exhaust valve seats

Fuel valve

Check fuel injection valve pressure & adjust

Fuel valve

pump

*

Check

&

adjust fuel injection pump

* The specific emissions related parts for the EPA/ARB regulations

EPA allows to apply Maintenance schedule for Emission related parts as follows.

−

Check Fuel Valve Nozzle and clean

Adjust, cleaning and repair of fuel injection Pump

and fuel valve nozzle

kW

x

130

1500 hours of use and at 1500

−

hour intervals

thereafter

3000 hours of use and at 3000

−

hour intervals

thereafter