Operation & Maintenance Manual

Installation

16

23221138 (5/08) Rev B

Installation

System Description - General

The VHP40RMD and VHP40RMG units are semi-packaged, or (optionally) totally self-

contained utility mount, reciprocating type, engine driven, air cooled air compressors. Each

unit is designed to operate at ambient temperatures from -10° F to 125° F (-23.3° C to 51.7° C).

Each model includes a 2-stage, 4-cylinder reciprocating air compressor, either a diesel or

gasoline driven engine with attached radiator and fan, compressor and engine air inlet

systems, a compressor lubricating oil system, a compressor discharge system, belt drive

system, electric compressor cooling fan, as well as basic instrumentation. An electric starter

(with onboard battery) is standard equipment. Separate air cleaners for the engine and each

bank of the compressor are installed, and a service reminder is fitted on the engine air cleaner.

Basic instrumentation includes compressor discharge air pressure gauge, hour meter,

warning lights for engine oil pressure, engine coolant temperature, and alternator output.

There is a safety shutdown system that monitors and stops the compressor in the case of high

engine coolant temperature, high compressor discharge temperature, or low engine oil

pressure. A starting bypass switch is provided in order to bypass the shutdown system during

starting until the engine oil pressure is high enough to activate the engine oil pressure switch.

The enclosure cabinet, in which the components are mounted, is of heavy gauge sheet steel

and is equipped with easy opening access panels for performing routine maintenance

functions.

The compressor module includes either a three cylinder gasoline engine or a three cylinder

diesel engine driving the air compressor pump via a double Powerband type "B" section belt.

The compressor pump is a high efficiency, air cooled two stage reciprocating unit, with

duplicate low pressure and a high pressure stages on either side of twin banks in a 90 degree

“V” layout. The pump features intercooling for both banks. Valve durability is increased through

the use of travel limiters on all intake and exhaust stainless steel reed-type valves. Lubrication

is splash type with mandatory use of synthetic oil. Construction is heavy duty cast iron

throughout.

Belt tension is adjustable using a convenient pair of tensioning bolts, which are adjusted after

loosening the four bolts that secure the motor bracket and air pump.

The compressor pump, engine, and drive system are fixed rigidly within relation to one another

on a sub-base. This sub-base is mounted on four vibration isolators, which in turn are attached

to the main base. This insolates shock and vibration from the main base and housing of the

unit, and in turn from the vehicle to which the unit is mounted. This provides simplicity of

mounting the compressor to the vehicle, as the rigid frame can be bolted directly to the body.

The discharge pressure of the compressor can be operated anywhere between 0 and 175

psig. Cooling for both the compressor and the hydraulics is sufficient for continuous operation

at full load.

An unloader valve triggers when the maximum set discharge pressure is reached, causing the

engine to throttle back and the reduced compressor output to be discharged overboard at very

low pressure. The nominal settings from the factory are unload at 175 psig and load at 145

psig. The unload pressure is adjustable at the unloader valve from 175 psig to 100 psig.

Summary of Contents for Ingersoll Rand VHP40RMD

Page 2: ...2...

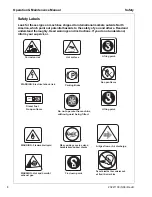

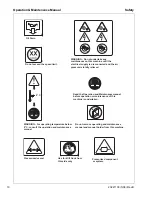

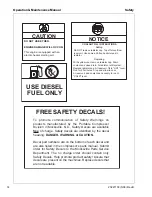

Page 5: ...23221138 5 08 Rev B 5 Safety...

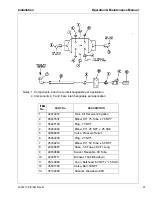

Page 15: ...23221138 5 08 Rev B 15 Installation...

Page 23: ...23221138 5 08 Rev B 23 General Data...

Page 26: ...Operation Maintenance Manual General Data 26 23221138 5 08 Rev B...

Page 27: ...23221138 5 08 Rev B 27 Operating Instructions...

Page 35: ...23221138 5 08 Rev B 35 Maintenance Lubrication...

Page 44: ...44 23221138 5 08 Rev B...