Installation

Operation & Maintenance Manual

23221138 (5/08) Rev B

17

Mounting Unit

Satisfactory installation depends upon the ability of the installer. Refer to the appropriate

foundation plan for the dimensions of the compressor package.

Choose a clean, relatively cool location for the compressor package, and provide ample space

around the unit for general accessibility and to ensure effective heat dissipation. Extreme care

must be taken in locating an air-cooled unit of this type so there is an unrestricted supply of air

to the cooling fan, which pulls air into the package. The air exiting the package must flow away

from the unit so that it may be readily dissipated to atmosphere without recirculating hot air to

the fan intake. Any recirculation of the cooling air may result in an excessively high compressor

operating temperature.

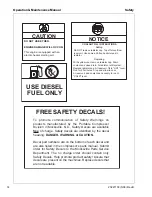

CAUTION

!

Do NOT mount the unit with either side of the machine facing forward on

a vehicle such that unrestricted airflow from motion of the vehicle may

enter the unit. Mounting the unit this way will cause wind milling of the

fan that can damage it. Mounting with this orientation must be done

behind a cab or other wind blocking structure.

The compressor package must be located so the instrument panel will be fully visible.

Exact level is not absolutely necessary, but it is recommended the unit be leveled with a

carpenter’s level set on the compressor housing. Leveling may be accomplished by shimming

the unit near the unit’s bolting holes. Use only steel shims. Mounting holes are provided on the

bottom of the base.

The mounting hole pattern of the compressor base and the optional fuel tank / receiver tank

module is identical, so that the tank module can be mounted later without drilling more holes

or separately using the same template.

Sufficient space must be provided at all service openings to provide ready access for service

and maintenance. For installations such as under the bed of a truck, it may be desirable to

provide a sliding mount tray for the compressor to facilitate servicing.

Summary of Contents for Ingersoll Rand VHP40RMD

Page 2: ...2...

Page 5: ...23221138 5 08 Rev B 5 Safety...

Page 15: ...23221138 5 08 Rev B 15 Installation...

Page 23: ...23221138 5 08 Rev B 23 General Data...

Page 26: ...Operation Maintenance Manual General Data 26 23221138 5 08 Rev B...

Page 27: ...23221138 5 08 Rev B 27 Operating Instructions...

Page 35: ...23221138 5 08 Rev B 35 Maintenance Lubrication...

Page 44: ...44 23221138 5 08 Rev B...