32

23221138 (5/08) Rev B

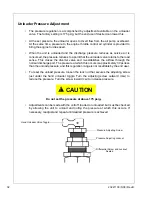

Unloader Pressure Adjustment

•

The pressure regulation is accomplished by adjustment available on the unloader

valve. The factory setting is 175 psig, but the end user if desired can lower this.

•

At the set pressure, the unloader opens to divert flow from the air pump overboard.

At the same time, pressure to the engine throttle control air cylinder is provided to

bring the engine to idle speed.

•

When the unit is unloaded and the discharge pressure reduces as service air is

consumed, the pressure reduces to a point that the unloader valve returns to the load

sense. This closes the diverter valve and re-establishes the airflow through the

normal discharge port. The pressure at which this occurs is approximately 30 psi less

than the unload pressure, and this regulation range is not resettable by the end user.

•

To reset the unload pressure, loosen the lock nut that secures the adjusting screw

just under the hand unloader toggle. Turn the adjusting screw outward (ccw) to

reduce the pressure. Turn the screw inward (cw) to increase pressure.

CAUTION

!

Do not set the pressure at above 175 psig.

•

Adjustments can be made with the unit off, loaded, or unloaded, but must be checked

by allowing the unit to unload and noting the pressure at which this occurs. If

necessary, readjust and repeat until desired pressure is achieved.

Hand Unloader Valve Toggle

Pressure Adjusting Screw

Pressure Adjusting Locknut

Differential Screw and Locknut

Sealed

Summary of Contents for Ingersoll Rand VHP40RMD

Page 2: ...2...

Page 5: ...23221138 5 08 Rev B 5 Safety...

Page 15: ...23221138 5 08 Rev B 15 Installation...

Page 23: ...23221138 5 08 Rev B 23 General Data...

Page 26: ...Operation Maintenance Manual General Data 26 23221138 5 08 Rev B...

Page 27: ...23221138 5 08 Rev B 27 Operating Instructions...

Page 35: ...23221138 5 08 Rev B 35 Maintenance Lubrication...

Page 44: ...44 23221138 5 08 Rev B...