Operation & Maintenance Manual

Maintenance/Lubrication

38

23221138 (5/08) Rev B

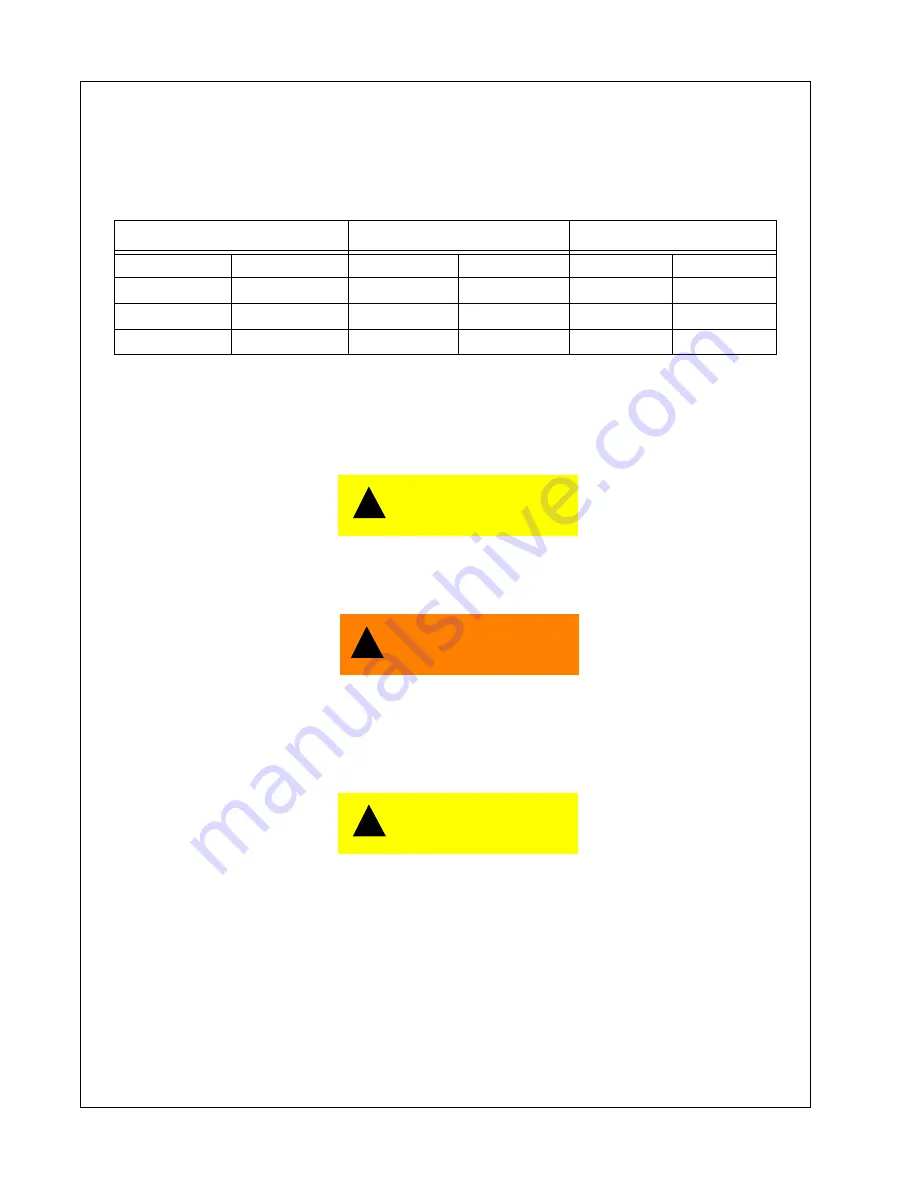

See the petroleum lubricant viscosity table below. The table is intended as a general guide

only. Heavy-duty operating conditions require heavier oil viscosity. Refer specific operating

conditions to your dealer for recommendations.

Synthetic oils meeting the specifications are preferred over petroleum-based lubricants.

NOTE: If you use a petroleum-based compressor lubricant and decide to

convert to All Season Select lubricant later, the compressor valves must

be thoroughly decarbonized and the crankcase must be flushed before

conversion.

CAUTION

!

Shorter oil change intervals may be necessary if unit is operated under

adverse conditions.

WARNING

!

Do not under any circumstances open any drain cocks, remove any plugs

or the oil filler plug from the compressor lubricating system without

making sure the air receiver system has been completely relieved of all

air pressure.

CAUTION

!

Some oil mixtures are incompatible with each other and result in the

formation of varnishes, shellacs or lacquers, which may be insoluble.

Such deposits can cause serious trouble. Where possible, try to avoid

mixing oils of the same type but different brands. A brand change is best

made at the time of complete oil change.

Temperature Around Compressor

Viscosity @ 37.8° C (100° F)

Viscosity Grade

° F

° C

SUS

Centistokes

ISO

SAE

<40

<4.4

150

32

32

10

40-80

4.4-26.7

500

110

100

30

80-104

26.7-40

750

165

150

40

Summary of Contents for Ingersoll Rand VHP40RMD

Page 2: ...2...

Page 5: ...23221138 5 08 Rev B 5 Safety...

Page 15: ...23221138 5 08 Rev B 15 Installation...

Page 23: ...23221138 5 08 Rev B 23 General Data...

Page 26: ...Operation Maintenance Manual General Data 26 23221138 5 08 Rev B...

Page 27: ...23221138 5 08 Rev B 27 Operating Instructions...

Page 35: ...23221138 5 08 Rev B 35 Maintenance Lubrication...

Page 44: ...44 23221138 5 08 Rev B...